Synthesis in DNI falls into 3 major categories:

1. Synthesis of

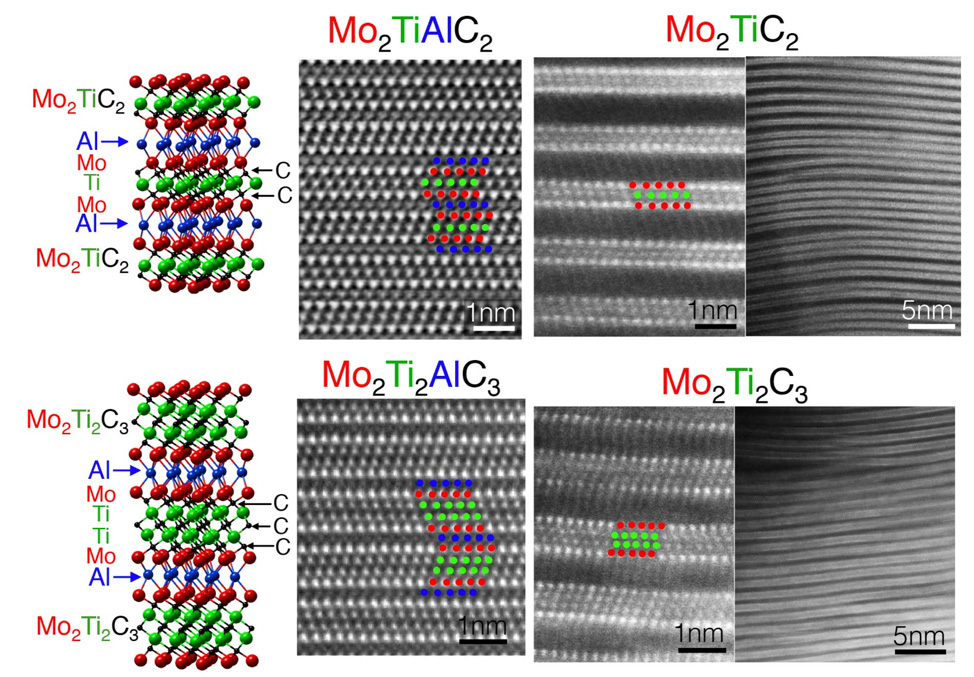

new MXenes through MAX synthesis.

Typically, MXenes are synthesized through a topochemical selective etching

process of MAX (Mn+1AXn) phase materials, where M is an

early transition metal (Ti, V, Cr, Nb, etc.) A is Al, Ga, Si, S, etc., and X is

carbon and/or nitrogen, and n is 1-3.1 By synthesizing MAX phase

materials (Ti3AlC2, V2AlC, Nb4AlC3,

Mo2Ti2AlC3, etc.) their corresponding MXenes

(Ti3C2Tx, V2CTx,

Nb4C3Tx, Mo2Ti2C3Tx,

etc.) can be synthesized.2-4 Each aspect of MXene

chemistry/structure including n (Ti2CTx vs. Ti3C2Tx),

M (V2CTx vs. Ti2CTx),

and X (Ti3C2Tx vs. Ti3CNTx)

affects the resulting properties and applications.5 Within MXenes, there are X general

classes synthesized to date: single M MXenes (Ti3C2Tx),

ordered-double transition metal MXenes (Mo2Ti2C3Tx),2 solid-solution MXenes (Ti2-xVxCTx),

and ordered divacancy MXenes (Mo1.33CTx).6 Thus far, over 30 MXenes have been

discovered, with the potential for hundreds more.

2. New

synthetic routes to etch MXenes.

When MXenes were first discovered, the method of production was the use of high

concentration HF.7 This HF would interact with the Al

layer in MXenes, selectively removing them, while leaving the Mn+1Xn

structure intact. This approach leads to the characteristic accordion-like

structure of MXenes. In today’s language, we call this multilayer MXene.

Afterwards, high-intensity sonication was carried out, leading to delamination

MXene, with sizes in submicron range. After this initial discovery, different

concentrations of HF were used, and this led to lower quantities of defects in

the initial MXenes, and thus better properties. At this stage, a variety of

intercalants (TMAOH, DMSO, etc.) were found to chemically delaminate the MXene

flakes, rather than mechanically. A new method was discovered, termed the MILD

method, that used a combination of HCl+LiF to produce HF in-situ and

simultaneously delaminate the MXene by intercalating lithium ions into the

structure.8 Since then, a new approach was

developed using a combination of HF+HCl, followed by a separate delamination

step with LiCl. These advances led to progressively larger and larger MXenes

(now >10 μm). In addition to increasing optimize methods for removal of

Al, there have been advances in selectively moving other A elements, such as Si

or Ga.9-10

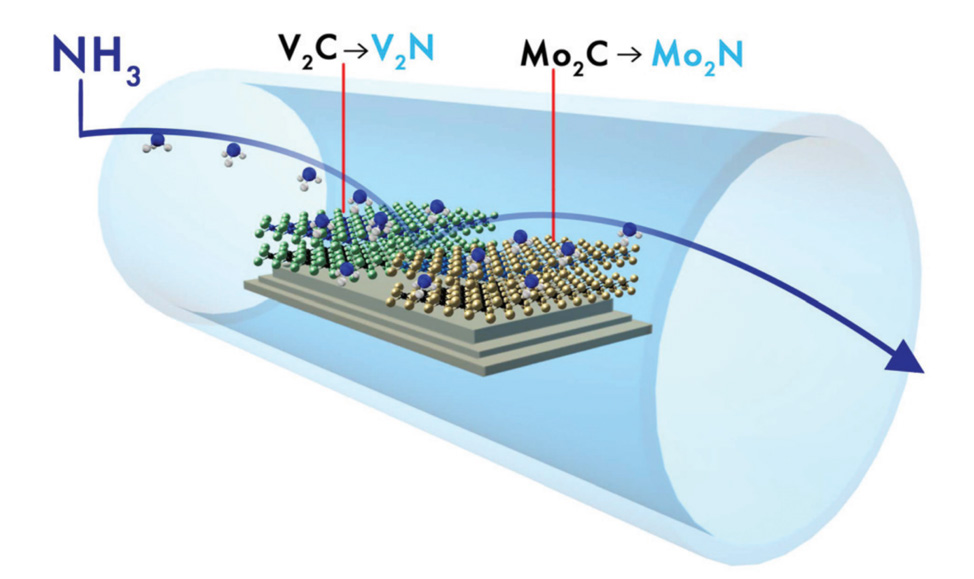

3. Nitridation

of MXenes. The

electronic properties of nitride-based MXenes were studied computationally, and

it was found that they should possess higher stability and electrical

conductivity, among other enhanced properties. However, synthesis of the MAX

phase precursors is a challenge; there has been successful reports of only a

few nitride MAX phases. Considering this, nitride materials are more

thermodynamically favorable, thus, with appropriate conditions, it is possible

to chemically convert carbide MXenes into nitride MXenes. Previously, we have

utilized NH3 gas at high temperatures (600°C) to convert Mo2CTx

and V2CTx into their nitridized forms, Mo2NTx

and V2NTx, respectively.11 These nitride MXenes had three

orders of magnitude higher electrical conductivity than their respective

carbide forms. Using a similar approach, we have also converted salt-template

grown oxides into 2D nitrides.12-13

Five Top Papers:

- Anasori,

B.; Xie, Y.; Beidaghi, M.; Lu, J.; Hosler, B. C.; Hultman, L.; Kent, P. R. C.;

Gogotsi, Y.; Barsoum, M. W., Two-Dimensional, Ordered, Double Transition Metals Carbides (MXenes). ACS Nano 2015, 9 (10) 9507-9516.

- Alhabeb,

M.; Maleski, K.; Anasori, B.; Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y.,

Guidelines for Synthesis and Processing of 2D Titanium Carbide (Ti3C2Tx

MXene). Chem. Mater. 2017, 29 (18), 7633-7644.

- Urbankowski,

P.; Anasori, B.; Hantanasirisakul, K.; Yang, L.; Zhang, L.; Haines, B.; May,

S.; Billinge, S. J. L.; Gogotsi, Y., 2D Molybdenum and Vanadium Nitrides Synthesized by Ammoniation of 2D Transition Metal Carbides (MXenes). Nanoscale 2017,

9, 17722-17730.

- Sokol,

M.; Natu, V.; Kota, S.; Barsoum, M. W., On the Chemical Diversity of the MAX Phases. Trends Chem. 2019, 1 (2) 210-223.

- Xiao,

X.; Wang, H.; Urbankowski, P.; Gogotsi, Y., Topochemical Synthesis of 2D Materials. Chem. Soc. Rev. 2018, 47 (23), 8744-8765.

References

- Sokol,

M.; Natu, V.; Kota, S.; Barsoum, M. W., On the Chemical Diversity of the MAX

Phases. Trends Chem. 2019, 1 (2) 210-223.

- Anasori, B.; Xie, Y.; Beidaghi, M.; Lu,

J.; Hosler, B. C.; Hultman, L.; Kent, P. R. C.; Gogotsi, Y.; Barsoum, M. W.,

Two-Dimensional, Ordered, Double Transition Metals Carbides (MXenes). ACS

Nano 2015, 9 (10) 9507-9516.

- Naguib, M.; Halim, J.; Lu, J.; Cook, K.

M.; Hultman, L.; Gogotsi, Y.; Barsoum, M. W., New Two-dimensional Niobium and Vanadium

Carbides as Promising Materials for Li-ion Batteries. J. Am. Chem. Soc. 2013,

135 (43), 15966-15969.

- Ghidiu, M.; Naguib, M.; Shi, C.;

Mashtalir, O.; Pan, L. M.; Zhang, B.; Yang, J.; Gogotsi, Y.; Billing, S. J. L.;

Barsoum, M. W., Synthesis and Characterization of Two-Dimensional Nb4C3

(MXene). Chem. Commun. 2012, 50, 9517-9520.

- Hantanasirisakul, K.; Alhabeb, M.;

Lipatov, A.; Maleski, K.; Anasori, B.; Salles, P.; Ieosakulrat, C.;

Pakawatpanurut, P.; Sinitskii, A.; May, S. J., Effects of Synthesis and

Processing on Optoelectronic Properties of Titanium Carbonitride MXene. Chem.

Mater. 2019, 31 (8), 2941-2951.

- Tao, Q.; Dahlqvist, M.; Lu, J.; Kota,

S.; Meshkian, R.; Halim, J.; Palisaitis, J.; Hultman, L.; Barsoum, M. W.;

Persson, P. O. A.; Rosen, J., Two-dimensional Mo1.33C MXene with Divacancy

Ordering Prepared from Parent 3D Laminate with In-plane Chemical Ordering. Nat.

Commun. 2017, 8, 14949.

- Naguib, M.; Mashtalir, O.; Carle, J.;

Presser, V.; Lu, J.; Hultman, L.; Gogotsi, Y.; Barsoum, M. W., Two-dimensional Transition

Metal Carbides. ACS Nano 2012, 6 (2), 1322-31.

- Alhabeb, M.; Maleski, K.; Anasori, B.;

Lelyukh, P.; Clark, L.; Sin, S.; Gogotsi, Y., Guidelines for Synthesis and

Processing of 2D Titanium Carbide (Ti3C2Tx

MXene). Chem. Mater. 2017, 29 (18), 7633-7644.

- Alhabeb, M.; Maleski, K.; Mathis, T.

S.; Sarycheva, A.; Hatter, C. B.; Uzun, S.; Levitt, A.; Gogotsi, Y., Selective

Etching of Silicon from Ti3SiC2 (MAX) Produces 2D

Titanium Carbide (MXene). Angew. Chem. Int. Ed. 2018, 130

(19), 5542-5546.

- Meshkian, R.; Näslund, L.-Å.; Halim, J.;

Lu, J.; Barsoum, M. W.; Rosen, J., Synthesis of two-dimensional molybdenum

carbide, Mo2C, from the gallium based atomic laminate Mo2Ga2C. Scripta

Materialia 2015, 108, 147-150.

- Urbankowski, P.; Anasori, B.;

Hantanasirisakul, K.; Yang, L.; Zhang, L.; Haines, B.; May, S.; Billinge, S. J.

L.; Gogotsi, Y., 2D Molybdenum and Vanadium Nitrides Synthesized by Ammoniation

of 2D Transition Metal Carbides (MXenes). Nanoscale 2017, 9,

17722-17730.

- Xiao, X.; Urbankowski, P.;

Hantanasirisakul, K.; Yang, Y.; Sasaki, S.; Yang, L.; Chen, C.; Wang, H.; Miao,

L.; Tolbert, S. H., Scalable Synthesis of Ultrathin Mn3N2

Exhibiting Room‐Temperature Antiferromagnetism. Adv. Funct. Mater. 2019,

29 (17), 1809001.

- Xiao, X.; Wang, H.; Urbankowski, P.;

Gogotsi, Y., Topochemical Synthesis of 2D Materials. Chem. Soc. Rev. 2018,

47 (23), 8744-8765.