The Nanomaterials Institute specializes in the study of MXene processing and polymer compositing, and the fundamental mechanical properties of MXenes.

Researchers in the DNI are interested in studying MXene interaction with polymers. Polymers are incorporated into a multitude of products and applications; however, they usually have low strength and modulus. MXene proves to drastically increase these important mechanical properties. In first principles calculations, MXene compositing has been identified as a promising candidate to improve the mechanical properties of many popular polymers. Additionally, MXene has been identified as having the highest modulus (330 GPa) of any solution-processed 2D material, making MXene a prime candidate for compositing. Researchers at Drexel are working to develop MXene into an ideal compositing component.

MXene has proven very beneficial for a wide variety of applications, including energy storage, EMI shielding, and sensors. Research efforts at Drexel works to discover MXene’s exciting mechanical properties and create composites that capitalize on these properties.

Lipatov, A., Lu, H., Alhabeb, M., Anasori, B., Gruverman, A., Gogotsi, Y., Sinitskii, A., Elastic properties of 2D Ti3C2Tx MXene monolayers and bilayers, Science Advances, 2018, 4, eaat0491.

Smart Textiles

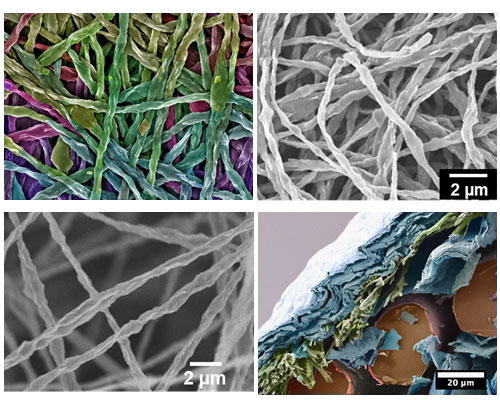

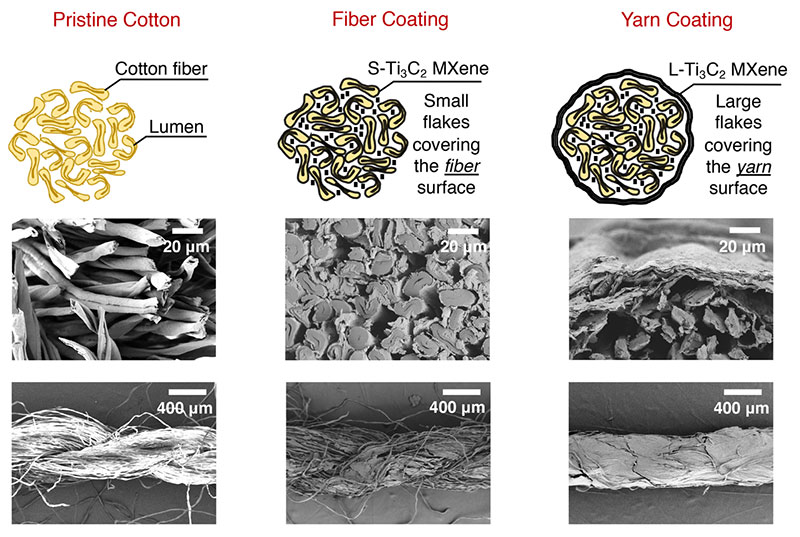

The field of smart textiles has been advancing rapidly over the last decade and has found applications in numerous industries, including sports, medicine, and military. Of many functions, these smart garments are capable of providing and tracking physiological data, retraining use of impaired limbs, and giving feedback to athletes on their performance. Many smart garments require power for operation, however, most of these garments still utilize conventional battery architectures such as coin or pouch cells, which are uncomfortable, unsafe, and can impose design limitations to the final device. Designing an energy storage device that is integrated into the textile itself will mitigate many of these challenges. The lack of conductive yarns that offer manufacturability and washability using existing textile processing technologies, in the same way as traditional yarns, has prevented manufacturers from utilizing conductive yarns. As such, the focus of smart textile research at Drexel is to develop flexible fiber and yarn electrodes that are scalable, meaning that meters of yarn electrodes can be produced, easily integrated into industrial-scale textile production, and that demonstrate high capacitance and cycling stability once knitted into a textile energy storage device. To do so, reserachers at Drexel are exploring different methods, including electrospinning and dip-coating, to incorporate MXenes into fiber and yarn architectures. The knittability of these materials is evaluated using 3D knitting machines at the Center for Functional Fabrics at Drexel.

The goal of this work includes developing a better understanding of the processability of MXene into fibers, such as how MXene concentration and MXene-polymer interactions affect the mechanical properties of the resulting fibers. Another goal of this work focuses on developing a new class of conductive yarns by integrating MXenes with everyday cellulose-based yarns, which combines high conductivity of MXene with industrial-scale textile processability and washability of cellulose-based yarns. This unique combination enables the realization of a myriad of functionalities in textiles such as energy storage and pressure sensing. Findings suggest that the utilization of this simple and scalable strategy for integration of advanced nanomaterials into commercial cellulose-based yarns is highly promising for industrial-scale production of conductive yarns, which are the building blocks of textile devices. Ultimately, this work will advance the development of scalable, flexible, and durable conductive fibers and yarns to power the next generation of smart garments.

MXene coated fibers

Levitt, A., Alhabeb, M., Hatter, C.B., Sarycheva, A., Dion, G., Gogotsi Y., Electrospun MXene/Carbon Nanofibers as Supercapacitor Electrodes, Journal of Materials Chemistry A, 2019; 7: 269-277.

Wang, Z., Qin, S., Seyedin, S., Zhang, J., Levitt, A., Li, N., Haines, C., Ovalle-Robles, R., Lie, W., Gogotsi, Y., Baughman, R.H.., Razal, J.M., High Performance Biscrolled MXene Yarn Supercapacitors, Small,

1802225, 2018.

Uzun, S., Seyedin, S., Stoltzfus, A. L., Levitt, A. S., Alhabeb, M., Anayee, M., Strobel, C. J., Razal, J. M., Dion, G., Gogotsi, Y., Knittable and Washable Multifunctional MXene‐Coated Cellulose Yarns. Advanced

Functional. Materials, 2019, 1905015. https://doi.org/10.1002/adfm.201905015

MXenes functional fabric for wearable devices

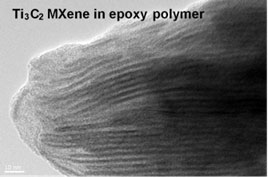

Composite Materials

Future technologies will rely heavily on composite materials from the aerospace industry to wearable electronics. Combining two or more distinctly different materials, composites allow us to design new systems and take advantage of unique properties otherwise unachievable with either starting materials. As a result, composites can be engineered for multifunctional use with properties such as low-weight, mechanically strong, electrically conductive and even heat resistant. However, composite research utilizing micrometer and nanometer sized materials have gained much attention due to unique characteristics that can be achieved at a small scale and with less material.

Polymer composite systems provide low-cost manufacturing, easy processing, chemical resistance and low weight, but when combined with nanomaterials additional properties can also be achieved. Two-dimensional nanomaterials, such as transition metal carbides (MXenes), are ideal candidates due to their high electrical conductivity, robustness, and thermal stability and can impart these desired properties to a polymer composite [1]. However, optimization of the polymer and MXene composites are required to achieve full multifunctional capabilities. To achieve this, composite research in the Nanomaterials Institute focuses on controlling the interface where epoxy and polyvinyl alcohol interact with MXene and improving the bonding between the two dissimilar materials. Additionally, maximizing the extent of MXene distribution within the polymer composite as well as particle size contributes an equal role in overall performance optimization.

Hatter, C. B., Shah, J., Anasori, B., Gogotsi, Y. "Micromechanical Response of Two-dimensional Transition Metal Carbonitride (MXene) Reinforced Epoxy Composites". Composites Part B (2019) under review.

Electromagnetic Applications of MXene

Within the Nanomaterials Institute, researchers work to explore the fundamental dielectric properties, mechanical properties and electromagnetic applications of MXene/polymer composites. MXene has demonstrated excellent electromagnetic interference (EMI) shielding capability which outperforms metals, carbon nanomaterials and conductive polymers. However, the mechanical properties of pure MXene coatings are relatively weak, such as wear resistance, adhesion and so on. Reseracher in the DNI hope to develop MXene/polymer composites that combine excellent mechanical properties, electrical conductivity, EMI shielding and/or electromagnetic wave absorption capability for practical applications of EMI shielding and antennas. Researchers in the DNI are also working to explore the fundamental electromagnetic interaction between polymer and MXene.

Figure. (a-c) SEM images of as-synthesized MXene/CNTs aerogels. (d) Schematic representation of possible mechanism of EMI shielding in MXCNT aerogel foam. (ACS Appl. Mater. Interfaces. 2019, doi.org/10.1021/acsami.9b12550)

Covalent Organic Frameworks (CFOs) and MXenes

COFs feature well-defined porous structures with an abundant choice of functional groups and heteroatoms. However, their intrinsic low conductivity limits their application in electrochemical fields. By introduction of COFs into the interlayer of MXenes, composite materials with well-defined porosity, heteroatoms and good conductivity may be obtained. In this work, researchers in the DNI study the interaction between COF functional groups and MXene surface groups, the influence of synthesis conditions on the composite conductivities and the integration of these composite into energy storage devices.

The synthesis of composites of MXene and covalent organic framework