Project Description

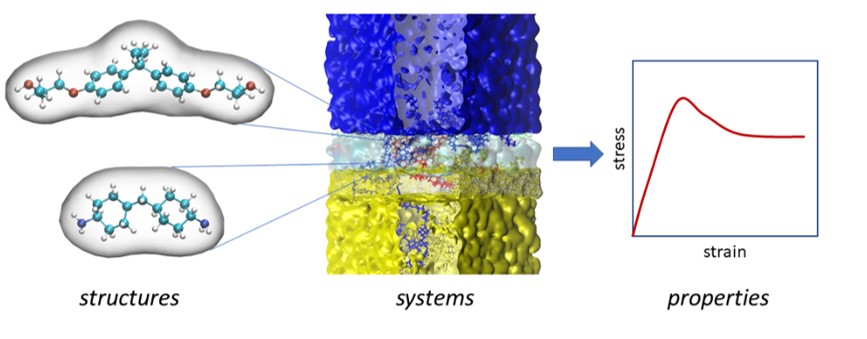

On-demand manufacture of precision, lightweight components in a variety of applications will depend upon designing new polymeric materials involving new building blocks and mixtures. Thermosetting polymers as feedstocks for 3D printing are prominent example of the need for more development, since they cannot be melted and extruded like traditional plastics, yet they promise vast improvements in strength per unit weight. The great chemical variety of thermoset building blocks makes exploration of chemical space using wet-lab experiments challenging. However, physical experiments in collaboration with molecular simulations has the potential to provide greater insights into what makes a 3D-printable thermoset an excellent material and what doesn’t. In this project, students will work with graduate students and postdocs in the Abrams group conducting molecular dynamics simulations of various thermosetting systems to measure the impacts of molecular structure and intermolecular interactions on macroscopic material properties essential to the design of 3D printing technologies.

Research Goals

- Generate molecular models and force-fields for new building-blocks

- Generate crosslinked systems

- Compute simulated material properties on those systems

Learning Goals

- How to conduct molecular dynamics simulations

- How to develop hypotheses on the roles of molecular structure and intermolecular interactions on material properties

- How to generate meaningful graphical representations of 3D molecular systems

Groups Conducting Research

Abrams Lab: https://research.coe.drexel.edu/cbe/abramsgroup/