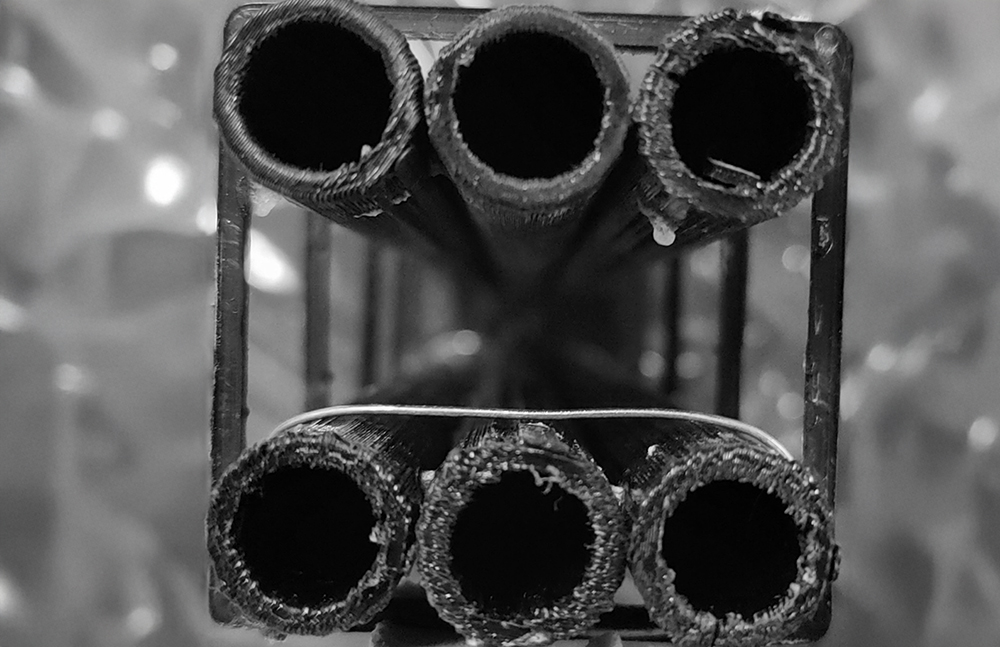

A cross-sectio of hollow rebar.

A cross-sectio of hollow rebar.

Drexel University researchers have developed a new approach to reinforce

concrete that takes inspiration from nature, specifically the hollow

structures found in plant stems. The research, recently published in the

Journal of Building Engineering, demonstrates significant

improvements in concrete's strength, toughness and ductility compared to

traditional reinforcement methods.

Traditional concrete reinforcement relies on solid steel bars (rebar) placed

within the concrete to provide tensile strength. The team, led by

Amir Farnam, PhD, associate professor of civil, architectural and environmental engineering,

and post-doctoral researcher Parsa Namakiaraghi, PhD, instead used

3D-printed hollow polymer tubes arranged in patterns that mirror natural

structures.

"Over millions of years of evolution, living organisms have developed

specific architectural elements with unique geometries, such as hollow

structures in plants, to enhance the mechanical properties of their

structures,” explains Namakiaraghi. "Plant stems need to be both strong and

flexible to survive the bending forces induced by natural elements such as

wind, and they achieve this through hollow, tubular structures which also

act as vessels for transporting water and nutrients. We've shown that we can

apply similar principles to improve construction materials."

The team developed what they call Engineered Polymeric Reinforced

Cementitious composite (EPRC), using sophisticated computer modeling to

predict performance before validating their designs through mechanical

testing. They created the reinforcement structures using 3D printing

technology, which allowed them to precisely control the geometry and

arrangement of the hollow tubes.

The hollow design proved superior to solid reinforcement in multiple ways.

Beyond the structural advantages of the tubular shape, the increased surface

area of the hollow tubes created stronger bonding with the surrounding

concrete. This enhanced the interface properties, combined with the tubes'

ability to better distribute forces, helped prevent the formation of cracks

and improved overall durability. Their results showed remarkable

improvements: concrete reinforced with hollow tubes demonstrated a 34%

increase in ductility, 93% increase in toughness, and 55% increase in

strength compared to identical samples reinforced with solid bars of the

same material.

"We were particularly impressed by the improvement in toughness - the

ability to absorb energy without rupture," says Farnam. "Traditional

reinforced concrete can be quite brittle, but our bio-inspired design allows

for more controlled deformation under stress, which is crucial for

structural safety."

The work was supported by the PA Manufacturing Innovation Program,

highlighting Pennsylvania's commitment to advancing construction technology

through additive manufacturing. The use of 3D printing not only enabled the

research but also points to potential future applications in construction.

Looking ahead, the team plans to explore scaling up the technology for

practical construction applications. They're also investigating different

materials and geometries that could further improve performance. The

research has implications beyond buildings - the principles could be applied

to infrastructure like bridges and roads, where improved durability and

crack resistance are especially valuable.

"This research demonstrates how we can create better performing materials by

learning from nature's time-tested solutions," adds Farnam. "As we continue

to develop this technology, we're excited about its potential to make our

built environment stronger, safer, and more sustainable."