Chen and Gadasu

Chen and Gadasu

Mac Chen and Ed Gadasu had the same considerations when it came to their

senior design project: they wanted something to round out their studies of

the materials field and something that felt significant. This led both of

them to pursue a project in polymers, and the opportunity to address the

challenges of recycling plastics carried the significance they sought.

“One of the biggest problems over the last 70 years is the rise of mass

produced, single use disposable plastics,” Chen noted. “They have a product

lifetime of just days, but their material physical lifetime is hundreds or

thousands of years. That kind of imbalance inevitably generates waste.”

Plastics have proved challenging for the recycling industry. It is

tremendously costly to sort out all the different types of plastic

packaging, but when different plastics are melted down together for reuse,

the different polymer molecules will not co-mingle, preferring to clump

together with other molecules of their own kind. This is called phase

separation, and the tension at the interface between these phases creates

structural flaws so great that the product is useless.

“We want to be able to create a functional recycled plastic,” Gadasu stated.

“What is the solution? To make two things mix, you want to make sure that at

the interface of the two plastics they can connect. You do this through the

use of an agent, called a compatibilizer, that improves the interfacial

properties of the two materials.”

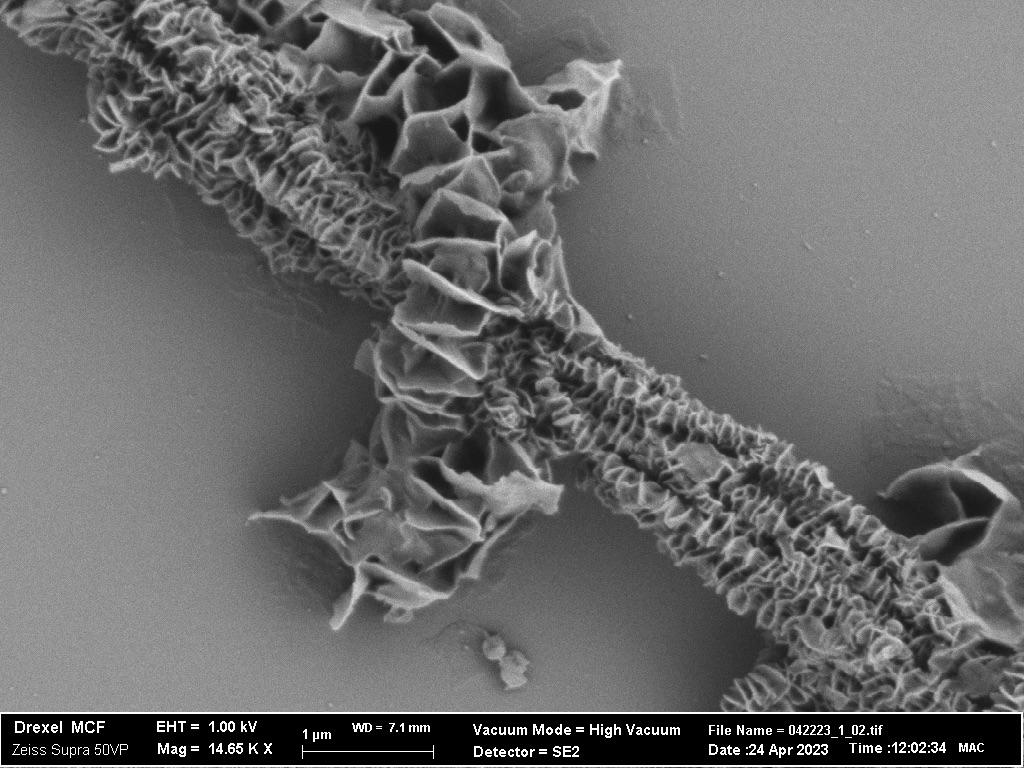

A microscope view of the nanohybrid material that Chen and Gadasu are using.

A microscope view of the nanohybrid material that Chen and Gadasu are using.

In their project, the duo are investigating the use of nanohybrid shish

kebabs (NHSK), developed by

Christopher Li, PhD

, professor of materials science and engineering, to serve as a

compatibilizer. Nanohybrid shish kebabs are carbon nanotubes, which serve as

the skewer in the metaphor, that are dotted with polymer crystals which are

like the meat or vegetables of the kebab. Li’s group has created NHSKs for

polypropylene and polyethylene, two most common polymers in plastic

packaging.

Chen and Gadasu are working to create a dual polymer NHSK that has both

polypropylene and polyethylene together on one carbon nanotube, with the

hope that this NHSK can get the separate phases of the polymers to link up

to the nanotube, decreasing the tension between the phases and improving the

structural integrity of the recycled product.

“It’s like polymer diplomacy,” noted Gadasu.

It’s a daunting but exciting undertaking, and both students realize this

road to discovery is likely much longer than their year of senior design.

They expect, however, that future senior design teams will pick up wherever

they leave off.

“We are hopefully laying the groundwork for 3D printing of recycled

plastic,” Chen said. “The idea is that down the road it may be possible to

create drawn out filaments and use them in an application where it can hold

its structural integrity and has certain properties. If we can reduce some

of the barriers to the recycling processes that exist and get more

structural integrity in our materials, that enables further research and

tuning of properties for certain applications.”