Members of the Drexel robotics team.

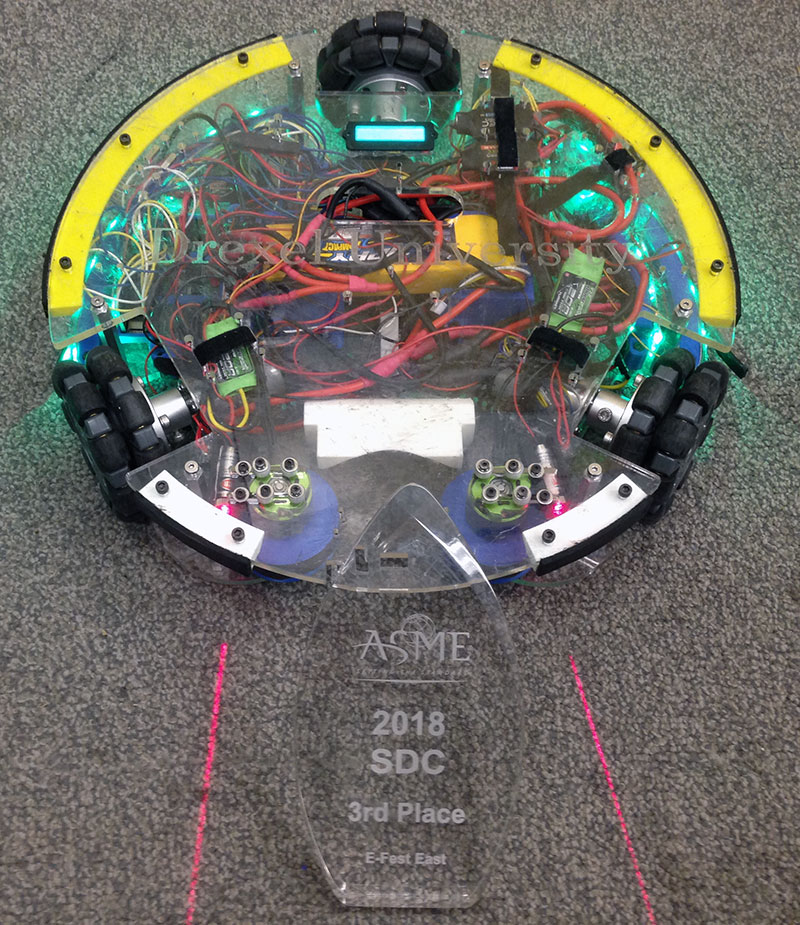

For five months, a College of Engineering team of undergraduates labored in AEL 173, designing a stackable, omni-wheeled robot with a lightweight acrylic platform, lasers, an Arduino-based Teensy board, and firing mechanisms tucked into a robust device that deploys tennis balls at 20 mph and plays soccer like nobody’s business.

Two weeks ago, that labor paid off: the robot, dubbed “THOR,” placed third out of 54 teams at the American Society of Mechanical Engineers (ASME) E-fest East 2018 Student Design Competition, held at Penn State.

And if the CoE team ever chooses to market their robot, every kid will want one.

The principal designers for THOR were mechanical engineering seniors Frederick Wachter, Sergio Machaca, and Matthew Wiese. They each invested 100 hours or more on the project during the pre-competition month, testing and refining a functionality that has, in the past, been unpredictable. Because last year’s ASME competition didn’t go so well for Drexel—“We were basically still assembling our robot on the way down to the competition,’’ said Wachter—the team hoped merely to put in a respectable performance this year. That they took third place was a happy outcome for a design that has seen several iterations.

The teams in the 2018 competition came from all over the United States, as well as Puerto Rico, Taiwan, and China. Competition criteria dictated that the device and all related components fit within a 50x50x50-centimeter wooden box and be able to play robot soccer, a nod to the upcoming FIFA World Cup games this summer. The energy source had to come from rechargeable batteries -- no pre-compressed springs or gas allowed -- and the device had to be maneuvered via remote control.

“Every year is a completely different theme. In 2014, it was a quadcopter that had to pick up a payload and maneuver it through a course. They try to keep the rules vague enough to allow for creative ideas and exploring different concepts. This year, we had a 5x5-meter playing arena. All the robots tried to get to the center to pick up the tennis balls, which were the soccer balls,” Wiese explained, laughing. “But it didn’t look anything like soccer.”

The seniors described THOR—which was actually three game robots: an attacker, a defender, and a spare—as a sort of goldilocks contender. Many of the collegiate teams simply repurposed RC cars for the competition. Others went overboard with complex designs that proved too cumbersome for the arena. One team had a $13,000 budget for a robot that didn’t work at all. But for THOR (which stands for Three Omni-wheeled Robot), the fit, the finish, and the functionality were just right.

“This was the only robot there that actually looked like a product by itself,” said Wachter. “A lot of that was due to the iterative design processes we had here. We can even pull out a bag of failed parts that we printed that didn’t work. The holes were too big or they printed elliptical instead of circular, or maybe we wanted a little more space after a fit-check and then we’d go back and print them out again. Sergio would do the printing and say, oh, this is slightly off; let’s do some modifications.”

One of the THOR robots.

Building the THOR robot was seriously labor intensive, he added. Several components were manufactured over five-to-12 hour time spans on two separate 3D printers, one of which was on loan from MEM professors Dr. Sorin Siegler and Dr. B.C. Chang.

Funding for the Drexel team’s $3,500 budget came from the Drexel ASME student organization and the Philadelphia ASME chapter. The THOR team had 13 members, all but two of them from CoE. In addition to Wachter, Machaca and Wiese, they are: Harrison Katz, Austin Miller, Alec Scherma, Jagteshwar Boyal, Michael Manuelli, Kristopher Lopez, Cassie Pezza, Mohammad Sahal, Darius Olega, and Sanjog Karki.

Wachter, Machaca and Wiese are pleased that the team is comprised of so many freshmen, which means they can successfully hand off the robotics torch at the close of the year. Questions about funding, design, using an Arduino, milestones, and scheduling, for example, have all been addressed in a set of Power Point slides for the use of a future robotics enthusiasts.

Faculty advisor Antonios Kontsos, an associate professor with the Department of Mechanical Engineering and Mechanics, said he was not surprised by the winning results.

“The technical subject of this competition required that this group not only use material learned in their courses, but also proved how they benefited from the diverse and highly competitive co-ops these students had. This shows exactly what Drexel students can do,” said Kontsos. “Their daily hard work, high technical skills and exceptional ethos have sparked enthusiasm not only among their peers but also among the faculty in the MEM department.”

The three seniors all have roots in the design process clear back to childhood. Machaca’s father was an electrical engineer and set up numerous small, do-it-yourself electronics projects with Machaca when he was young. Wachter’s father, also an electrical engineer, fostered his son’s interests with a room-sized train set that was hauled out, set up, and tweaked each Christmas. Wiese spent a great deal of time modifying RC cars when he was little and, more recently, built the motorized skateboard that today transports him around campus.

“I like to make things that move,” Wiese said.

The robotics work at Drexel has served all three undergraduates well as they contemplate graduation next month. Wachter is considering several offers in the robotics field. Machaca will pursue his PhD in mechanical engineering at Johns Hopkins University. And Wiese will return to the Naval Research Laboratory where he enjoyed a co-op working on ground and space robotics.

“We really wanted to make something that was uniquely ours and that we could take pride in,” said Machaca of THOR. “We wanted to bring something to the competition that would be competitive and have a chance of placing, and getting recognition for our work. I feel like that’s why we’re so invested in this project. It’s not just all the years that we’ve been working in this program. It’s our personal goals for the future, as well.”