Medical Device Startup Nephria Bio to Use Drexel's MXene Filter Materials in Wearable Artificial Kidney Technology

- ‘Too Much Going On’: Autistic Adults Overwhelmed by Nonverbal Social Cues

- Drexel’s College of Nursing and Health Professions Receives $1 Million for Scholarships from the Bedford Falls Foundation – DAF to Address Nursing Workforce Shortage

- U.S. Department of Education Provides Final Approval of Drexel and Salus Merger

- Spotting Bad Batteries Before They Malfunction

MXene materials will be a key element in the production of Nephria Bio's wearable artificial kidney technology

Drexel University’s MXene material is one step closer to transforming the lives of people suffering from end-stage kidney disease. Nephria Bio, Inc., a U.S.-based spin-off of the South Korean medical device company EOFlow Co., Ltd., has signed a licensing agreement with the University to use the two-dimensional material, discovered at Drexel, as a filter in a wearable artificial kidney device it is developing. The technology could allow many of the millions of people suffering from end-stage kidney disease worldwide to move more freely, without spending hours each week anchored to large dialysis machines.

“Our fundamental study of titanium carbide MXene supported by NSF showed that MXene is biocompatible, able of adsorbing a variety of small molecules, and holds a lot of promise in medical applications, so it is exciting to see it applied for improving and really changing dialysis — an area of need in health care that can help millions of people,” said Yury Gogotsi, PhD, Distinguished University and Bach professor in Drexel’s College of Engineering, who is a world leader in developing and studying MXenes.

In the late stages of kidney disease, the kidneys have trouble filtering fluids and small molecules, including urea, and some of these molecules become toxic in the body when they begin to accumulate. Dialysis supports the kidneys in filtering toxins and excess fluids from the blood, but the process is time-consuming and requires patients to remain attached to immobile dialysis machines.

“This work could give hundreds of thousands of people with kidney disease the ability to live life more freely and fully,” said Meera Harhay, MD, an associate professor of Medicine in Drexel’s College of Medicine, who has been working with Gogotsi to study MXene’s application in dialysis. “A wearable artificial kidney would allow people suffering from kidney disease to more easily work and travel and maintain a more active lifestyle, which has been associated with positive health outcomes.”

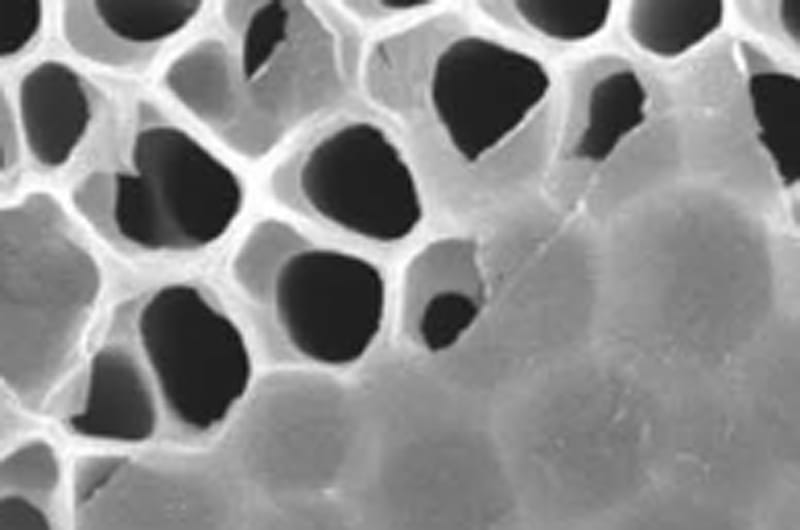

A single facility-based hemodialysis session can require up to 200 liters of purified water to clear the build-up of urea and other toxic molecules from a patient’s blood. Developing a portable dialysis machine means figuring out how to reduce the amount of water the wearer would have to carry with them.

MXene is the solution, according to Jesse Kim, founding CEO of Nephria Bio and its parent company, EOFlow, because it filters urea and other electrolytes well enough that a single liter of water could be quickly cleaned and reused for the entirety of the process.

“In order to develop a wearable dialysis device, you need a material that can filter urea, which is a very, very small molecule that is also very soluble, it dissolves in water so well that it’s really hard to filter,” Kim said. “It’s the most difficult toxin to filter. And that’s why dialysis takes so long. If you go to a dialysis center, it takes 4-6 hours per session.”

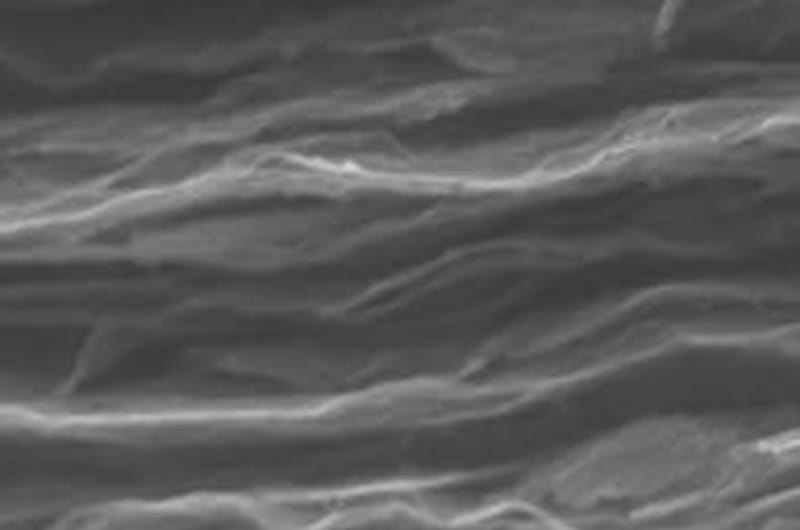

MXene is a two-dimensional material just a few atoms thick that has demonstrated a number exceptional abilities since its discovery in Drexel’s College of Engineering in 2011. Among them, the ability to filter tiny particles from liquid, which researchers in the Department Materials Science and Engineering identified several years ago, made it a prime candidate for use in dialysis.

"Two technologies are essential to develop wearable artificial kidneys; One is a small, light actuator with low power consumption, and the other is an efficient material for urea filtration. Nephria Bio secured them both—the proprietary electroosmotic pump technology from EOFlow, and the filter technology from Drexel University,” Kim said. “With the unique combination of these enabling technologies, Nephria Bio feels that it can substantially enhance dialysis therapy for kidney patients.”

Drexel researchers Gogotsi, who discovered MXenes along with fellow College of Engineering professor Michel Barsoum, PhD, and Harhay, a kidney disease specialist, have been working with Kim with support from the Coulter-Drexel Translational Research Partnership Program to combine MXene with EOFlow’s patented electrochemical actuator pump, to produce a lightweight-but-powerful filtration device that will enable portable dialysis.

The EOFlow pump is the key component of a disposable insulin patch, which recently entered the market. It launched Nephria Bio in January 2021 with the specific goal of exploring how it could be used in dialysis.

Nephria Bio’s plan is to use the pump and MXene material to produce a lightweight, highly efficient filtration system that would enable reuse and recycling of the filtration water, called dialysate. Putting the technology in a flexible, wearable, cartridge-based system, called EOPump-based Continuous Ambulatory Renal Replacement Therapy (EOCARRT™), will allow ambulatory dialysis. The system could supplement or bridge traditional dialysis therapy and, ultimately, supplant it — depending on the therapeutic needs and how the device performs, Kim said.

“Working with Nephria Bio through the Coulter program has revealed the promise of MXene materials in biomedical technology. This collaboration is taking the work of many Drexel researchers one step closer to realizing its potential as a medical application” said Kathie Jordan, PhD, director of the Coulter-Drexel program.

Drexel News is produced by

University Marketing and Communications.