Plasma Engineering Lab

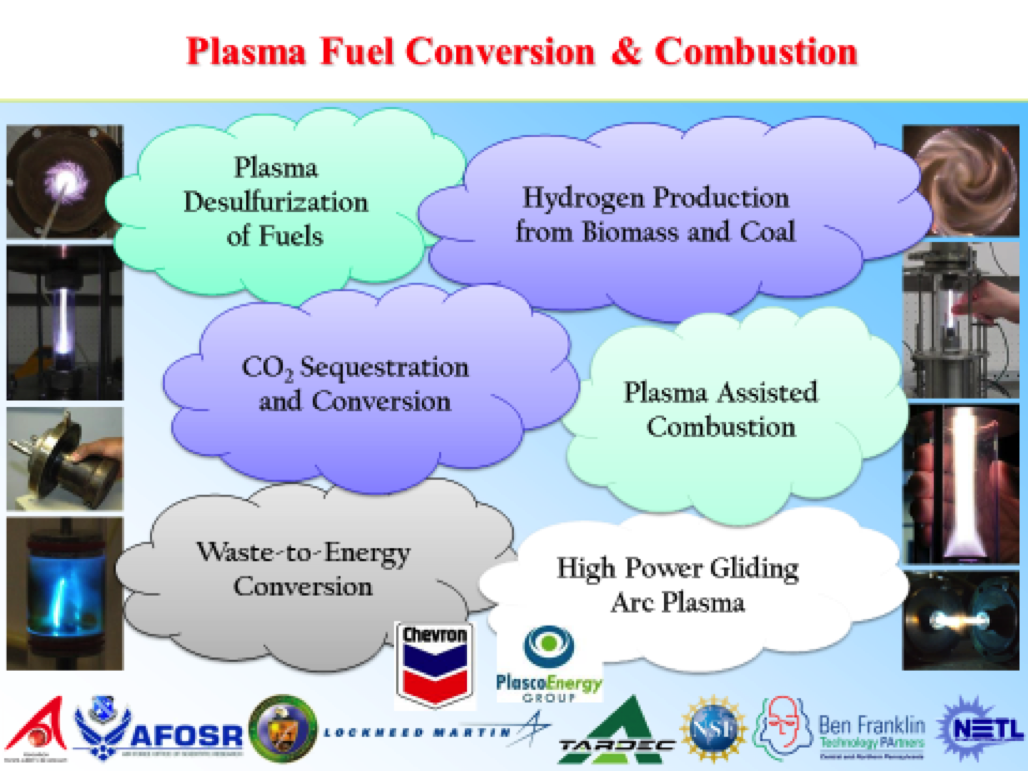

Plasma Engineering Lab is a division of the C. & J. Nyheim Plasma Institute focused on applications of Gliding Arc Plasma to Industry. The growing energy consumption and increasing concern in environmental and pollution problems imply a large amount of efforts to develop cleaner and more efficient energy production systems. A major factor in developing new energy systems is the requirement for hydrogen-rich gas fuel. Hydrogen-rich gas could be obtained from various hydrocarbons using external catalytic reformers but they are usually heavy, large, have slow response, use expensive catalysts and have difficulties reforming hydrocarbon fuels heavier than methane and methanol (such as gasoline, diesel, JP8, oils, etc.). Elimination of these problems may be possible by use of gliding-arc plasmatrons, developed at Nyheim Plasma Institute.

Gliding-arc plasmatrons provide highly controllable plasma-chemical activation of gases at elevated temperatures. Non-thermal plasma can be used to reform a wide range of hydrocarbon fuels, and particularly heavy hydrocarbons such as diesel, JP8, gasoline and heavy oils into synthesis gas without the use of a catalyst. The key feature of gliding arc reforming process is that non equilibrium plasma is used only as a catalyst thus ensuring minimum energy consumption (1-2% of fuel heating value).

In plasma reformer- fuel cell system the plasma reformer could produce a hydrogen-rich gas directly for Solid Oxide Fuel Cell (SOFC). The combination of a plasma reformer with SOFC is especially attractive since it could result in a very compact and simple system. SOFC auxiliary power units (APU) on diesel trucks are important for generating power during engine shut off. It is also important for military applications since modern vehicles carry a lot of additional electronic equipment. The plasma assisted reformer developed at Nyheim Plasma Institute, is ideally suited to meet these requirements.

In the past several years the plasma fuel reformer has demonstrated hydrogen rich gas production with efficiency 90-95% on a broad range of hydrocarbon fuels (gasoline, diesel, methane, and biofuels). Researchers of Nyheim Plasma Institute developed a novel cyclonic reactor with non-equilibrium gliding arc for reforming of solid hydrocarbons such as coal and biomass. This technology has the capability to turn a powdered coal or biomass into synthesis gas and then to liquid synthetic fuel.

NPI also developed a plasma technology of hydrogen sulfide dissociation using our patented Gliding Arc Tornado (GAT) reactor. This non thermal plasma process is very important for the oil industry since hydrogen sulfide is a byproduct of oil refining. In conventional methods of H2S processing, such as the Claus method, all hydrogen from H2S is transformed into water but using a plasma process it could be recirculated back into oil refining process.

In addition, plasma technology can be very efficiently used for municipal waste treatment providing possibilities of development of an integrated plasma system converting residual solid material (glass and metals) into rock-like vitrified mass; or converting organic materials into high quality synthesis gas acceptable for use in an internal combustion engine for power generation; or in a Fisher-Tropsch process for liquid fuel production.

Non Thermal Plasma Energy Applications

- Hydrocarbon fuel reforming with production of syngas. Such a process can be applied to:

- Liquid – gasoline, diesel, heavy oils, bio-oils, glycerin etc.

- Gas- natural gas

- Solid- coal, biomass

Methods include partial oxidation, steam reforming, and autothermal reactions.

-

Hydrocarbon fuel reforming without CO2 release. Hydrogen and solid carbon suboxide is produced.

- Cleaning of dirty gaseous products of coal, biomass, and municipal wastes gasification.

Tar, light and heavy hydrocarbons are removed

- Dissociation of hydrogen sulfide (H2S). Hydrogen sulfide is a product of oil refining with production of hydrogen and sulfur. The dissociation of H2S can also be applied for fuel desulfurization.

- Upgrading of oil/other hydrocarbons with plasma activated natural gas. Plasma excited methane will be incorporated into liquid hydrocarbons with production of additional amounts of oil.

Other Gliding Arc Plasma Applications

- Production of plasma acid. Could be used for surface cleaning, oil industry and agriculture.

- Production of syngas for Fuel Cell. Syngas produced in plasma reformer could be used for Solid Oxide Fuel Cell. After water shift stage the produced H2, CO2 mixture could be used for PEM Fuel Cell.

- Automotive industry. Small gliding arc plasmatron installed on a vehicle can produce syngas that will be used for addition to the engine. This can decrease engine emissions and improve engine efficiency. Also plasma produced syngas could be used for diesel exhaust gases aftertreatment from NOx.