Focus Areas

Innovation through textile fabrication involves addressing the

industry’s grand challenges, including the need for new ways to model

and design textiles pre-fabrication, as well as new tools and fabrication

techniques to enable scalability and further automation. Advances in these

fundamental building blocks will enable new ways for advanced manufacturing to

progress in the United States, create a need for new skill sets and expertise,

and enable the incorporation of new functionality into textiles.

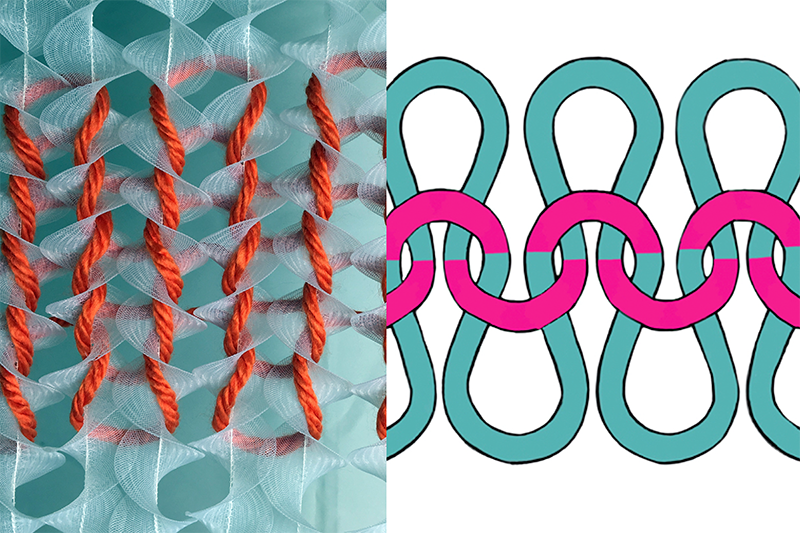

Virtual Textile Modeling and the Digital Twin

One of the textile industry’s grand challenges involves the need for new

ways to physically model and design textiles pre-fabrication. Historically

this has been a major challenge due to the complex dynamics inherent in

textile structures. Through a joint effort of CFF and Professor Randall Kamien

of the University of Pennsylvania, with ongoing funding support from the US

Army DEVCOM, new design tools are in development to enable the modeling of

knit structures using a digital twin.

Related: Computational Modeling of Knitted Textile Architectures | Self-Folding in Weft Knit Textiles

Advanced Manufacturing & Automation of Textile Manufacturing

The Center’s

R&D projects often involve working with new materials that require

modification or adaptation to industrial equipment, or even the development of

new equipment that allows automated manipulation of soft or flexible yarns,

fibers or fabrics. The range of equipment in the Center’s Innovation

Space allows for the simulation of a mini-factory environment. At the

beginning of the Covid-19 pandemic, this capability allowed the Center to

pivot to full-time manufacturing of knitted masks for several months to supply

essential Drexel staff and the broader community.

The Center’s

R&D projects often involve working with new materials that require

modification or adaptation to industrial equipment, or even the development of

new equipment that allows automated manipulation of soft or flexible yarns,

fibers or fabrics. The range of equipment in the Center’s Innovation

Space allows for the simulation of a mini-factory environment. At the

beginning of the Covid-19 pandemic, this capability allowed the Center to

pivot to full-time manufacturing of knitted masks for several months to supply

essential Drexel staff and the broader community.

Related: Masks | Exo-Skin Soft Haptic Exoskeletal Interface

E-Textile Design, Fabrication & Integration

R&D Projects at

the Center frequently involve using conductive textiles to create active and

responsive devices. Using a wide array of conductive yarns and fibers with a

range of electrical properties and suitability for textile integration, the

Center’s work continues to explore the potential of fabrics that can

transduce input and transmit electrical signals. This includes work on the

knitted capacitive touch sensor developed by the Center, as well as

development of frameworks for signal processing and design kits for soft

systems.

R&D Projects at

the Center frequently involve using conductive textiles to create active and

responsive devices. Using a wide array of conductive yarns and fibers with a

range of electrical properties and suitability for textile integration, the

Center’s work continues to explore the potential of fabrics that can

transduce input and transmit electrical signals. This includes work on the

knitted capacitive touch sensor developed by the Center, as well as

development of frameworks for signal processing and design kits for soft

systems.

Related: Capacitive Touch Sensor | Textile Energy Storage | Smart Fabric

Bellyband | Smart Fabric Sensors and Actuators | Touch Sensitive for Hubo | Wi-fi

Power Harvesting | MXene Yarn