Capabilities & Expertise

Manufacturing Level Equipment for Rapid Prototyping

The suite of

manufacturing tools available at the Pennsylvania Fabric Discovery Center (PA

FDC) at the Center for Functional Fabrics (CFF) offer full scale industrial

production potential. Our manufacturing floor includes state-of-the-art weft

knitting, sample warp knitting, sample weaving, fabric embroidery and yarn

assembly equipment. There are additional rooms for testing, yarn storage,

assembly, dye and finishing. The PA FDC @ CFF utilizes this equipment to push

the current boundaries of functional fabrics, smart garments, novel materials,

and wearable technology. The ability to explore technologies via our

end-to-end rapid prototyping facility allow for direct translation to high MRL

production of new technologies.

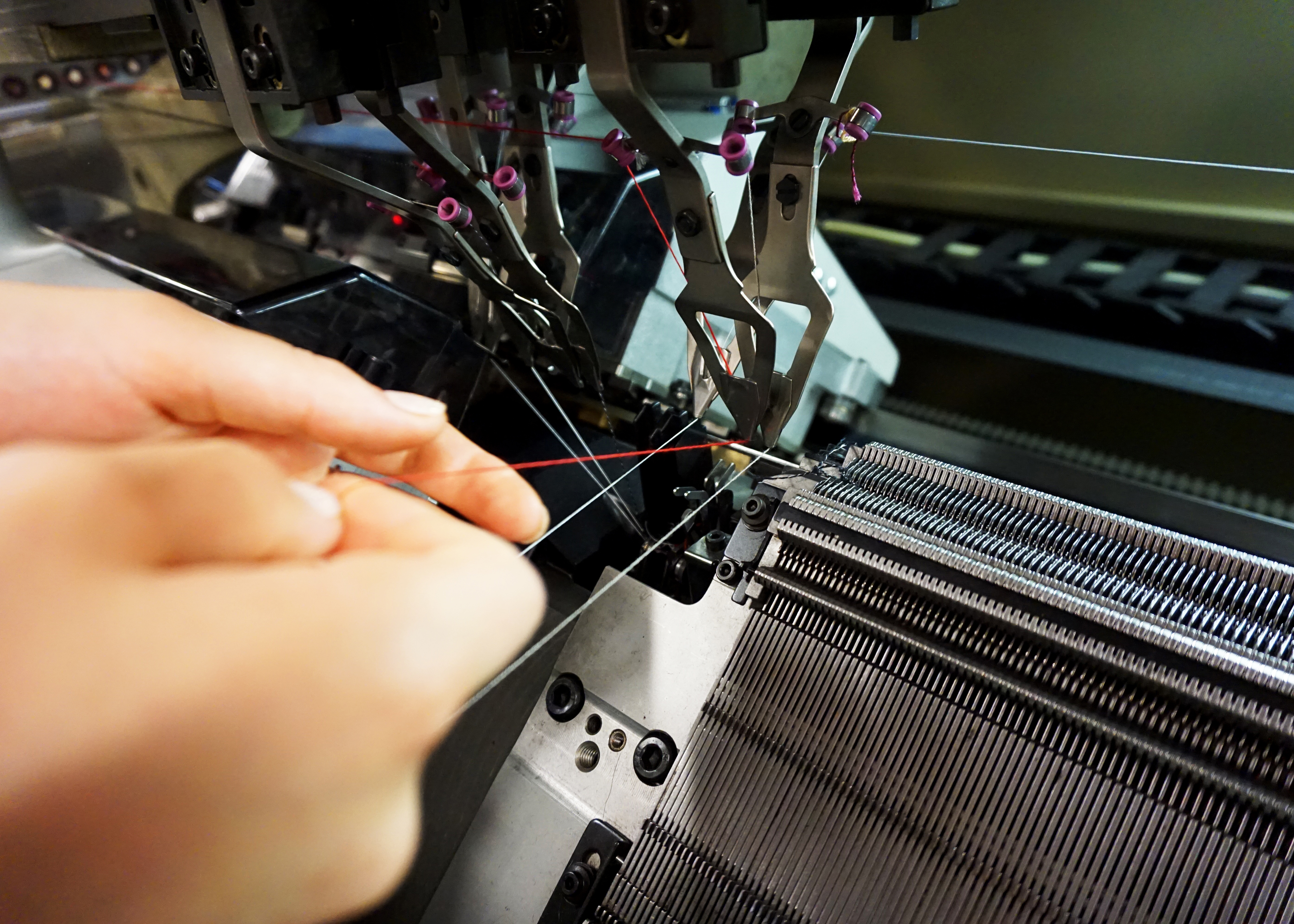

Flat Weft Knitting

Six industrial flatbed weft knitting machines (gauges between 8 and 15; Shima

Seiki SSG122SV, SWG041N, MACH2X, SWG091N2, Mach2XS, SVR123SP) with

accompanying state-of-the-art programming, modeling, and design system

computers (6 SDS-ONE APEX workstations). All machines provide seamless

knitting capabilities, and two machines provide Wholegarment™

capabilities. Traditional plating and iPlating capabilities also

available.

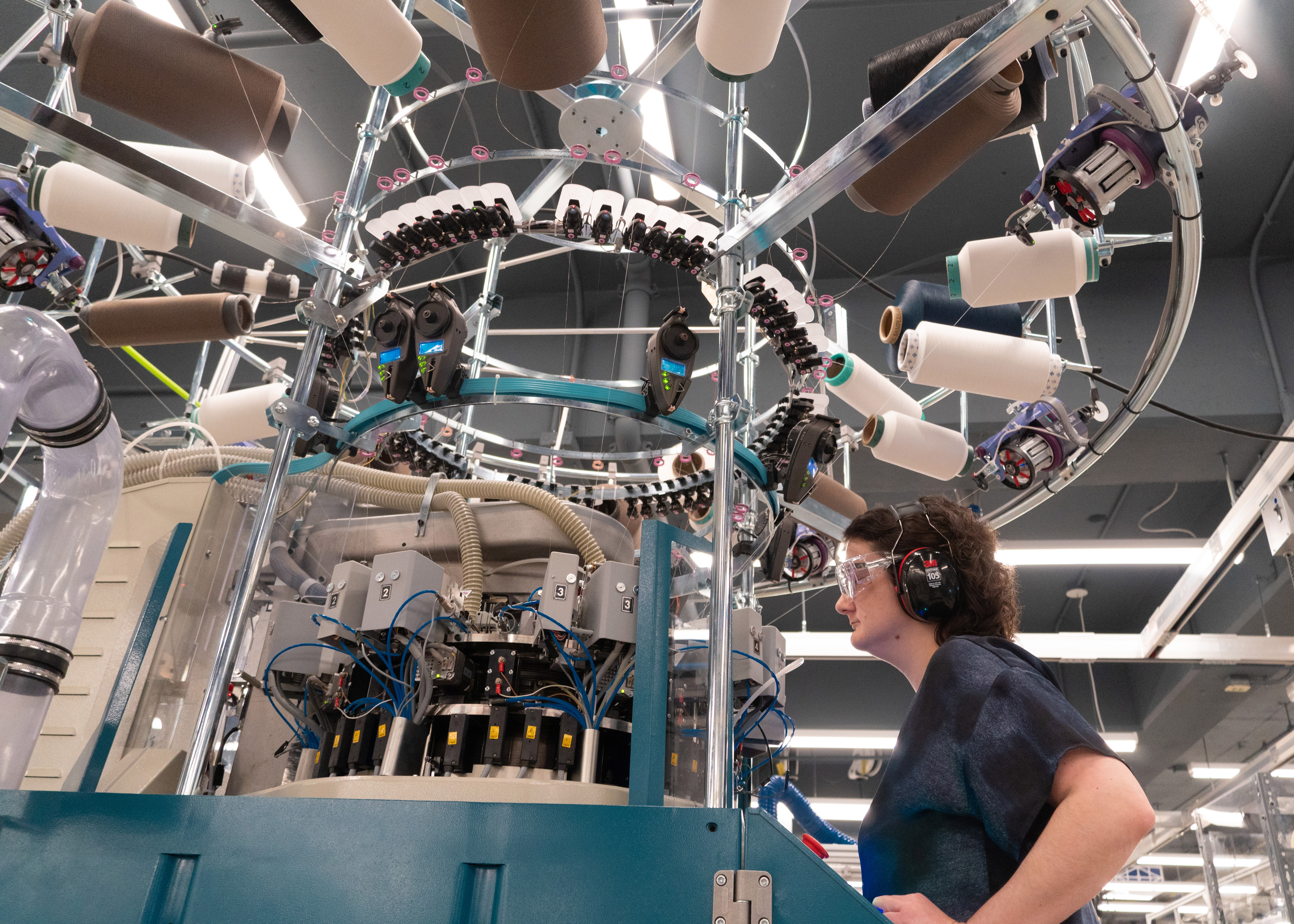

Circular Weft Knitting

Circular weft knitting machines with coarse and fine gauges for medium to

large garments (Santoni SM8-EVO4J) and shoe uppers (Lonati DC88-2C).

Sample Weaving (CCI Tech Inc.)

A fully automatic sample weaving loom (The Studio), flexible warping machine

for preparing beams (Mini Lutan Single-End Warping Machine), and sizing

machine suitable for experimental batch sizes (SS600 Single-End Sizing

Machine). Warping machine also produces suitable beams for warp knitting

equipment. Sizing machine may be used for yarn preparation for a variety of

machines.

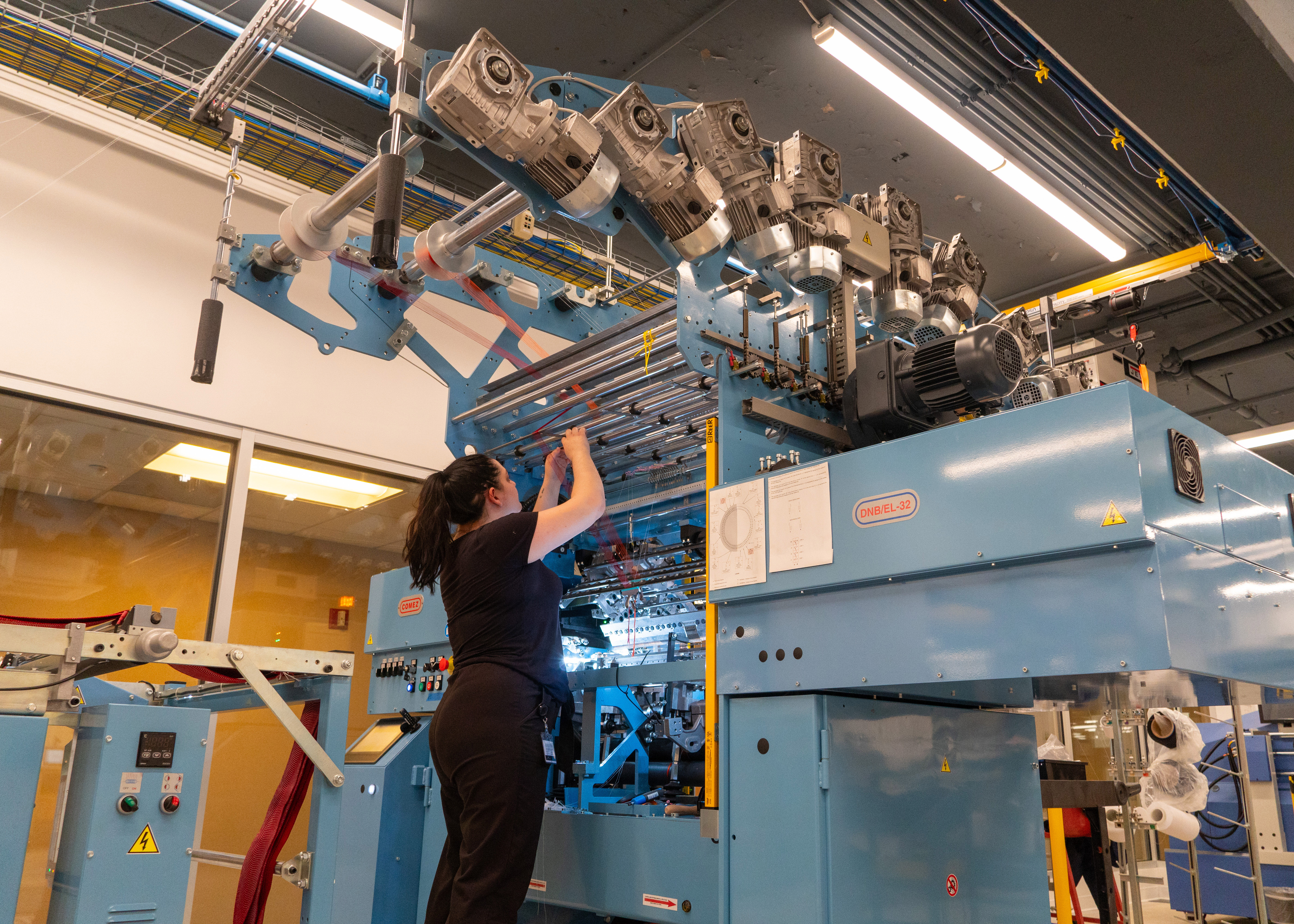

Sample Warp Knitting

Comez DNB/EL-32 warp knitting machine with electronic double needle bed warp

knitting machine to produce a wide range of articles applicable to technical

uses, medical uses, and footwear, with yarn/fiber lay-in capabilities.

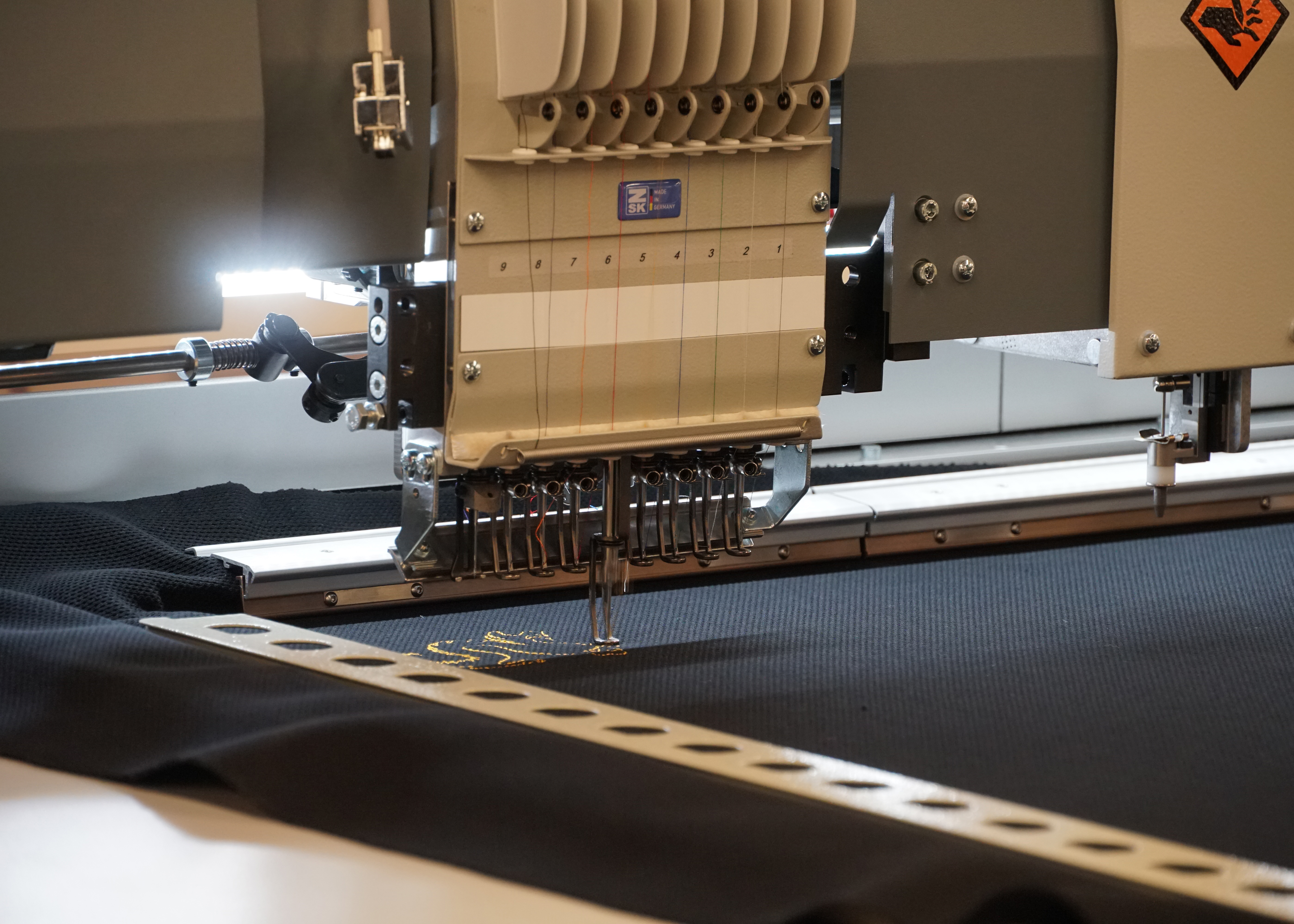

Embroidery

ZSK JGVA 3-Head Technical Textile Embroidery Machine allowing for

incorporation of technical yarn materials such as conductive threads, as well

as larger components such as silicone tubing, carbon fiber tows, etc. Capable

of generating high surface area stitching and automated placement of small

electronics such as RFID or LED. Helps derisk prototype development through

proof-of-concept validation.

Yarn Management, Assembly, & Braiding

Hybrid, multi-function equipment for yarn twisting, yarn covering, yarn

blending (Agteks DirecTwist 2C6D6, DirectCover 2S, Simet Twisting Machine) and

braiding (2 16-spool New England Butt Company Braiding machines). Sample

Twister was created at PA FDC to provide a modular twisting set-up for fragile

or short lengths of novel materials. Yarn processing accessories to adjust and

control angle, rate and directionality of yarn feeding into textile production

machinery (creels, yarn accumulators, servo feeders, LGL Spin Feeders and

Compact Feeders).

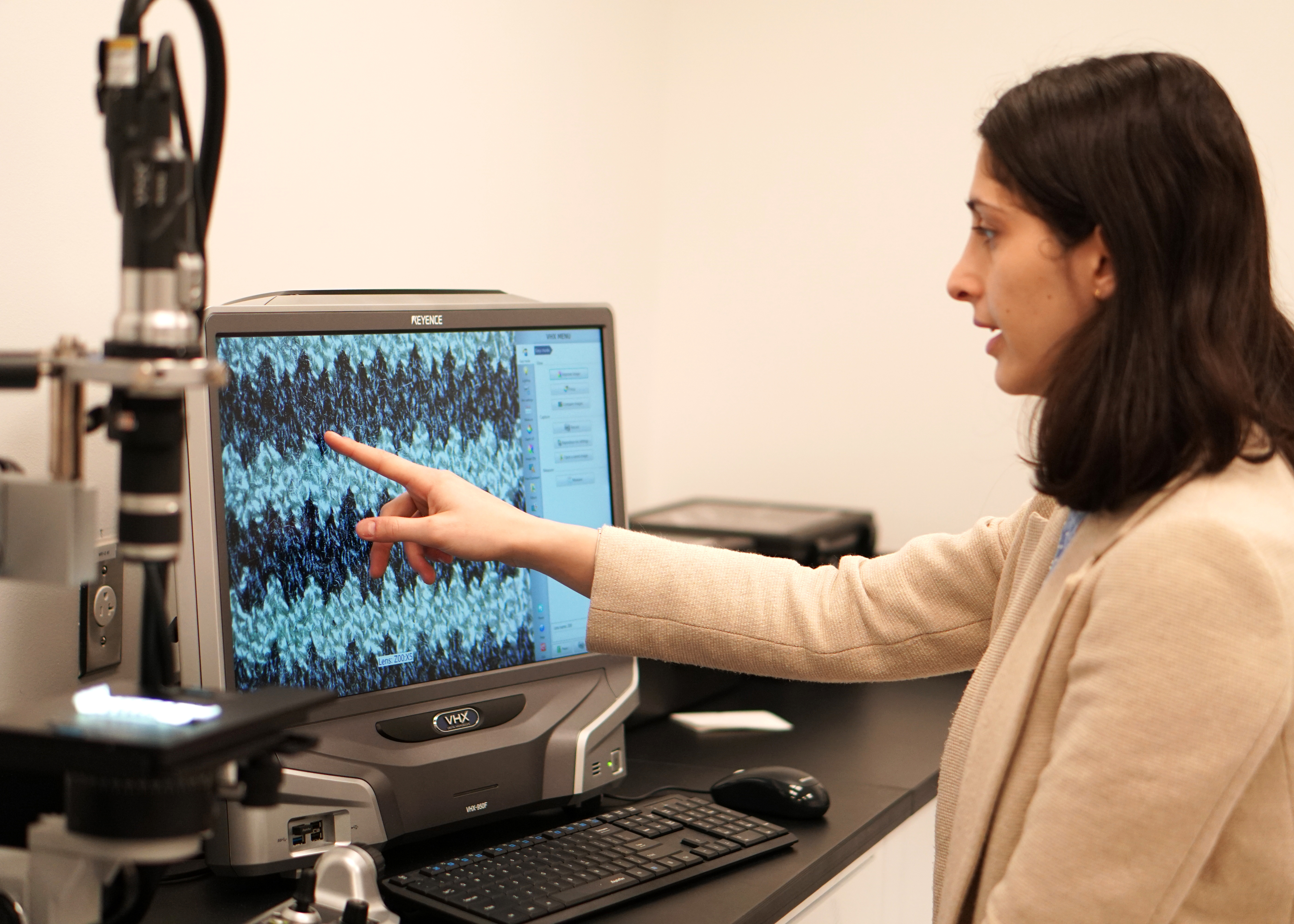

Testing

A variety of equipment suited for advanced analysis of fibers, yarns, and

textiles, through optical imaging and physical characterization of mechanical

properties, assembly characteristics, and performance characteristics.

Equipment at PA FDC includes, but is not limited to, Keyence VHX-950F

stereoscopic microscope, Electronic Twist Tester, Yarn Count Tester, Yarn Wrap

Reel, Shimadzu AGS-X Universal Tester, Pfaff Seam Testing Station, SDL Atlas

Martindale Abrasion and Piling Tester.

General Prototyping Tools

3D body scanner for generation of accurate body measurements (SizeStream SS20

3D Body Scanner), 3D printers, laser cutter, and a variety of state-of-the-art

textile assembly and finishing tools for constructing garments and other

product prototypes including, but not limited to, Pfaff 8301 Ultrasonic

Welding/Sewing Machine, 8303i Hot Air Seam Sealing Machine, Juki Lockstitch

Machine, Juki Coverstitch Machine, Merrow MB-4DFO 2.0, Wascomat Washer and

Dryer, Reliable Steam Iron, Commercial Vacuum Ironing Board, Powersonic

Benchtop Ultrasonic Cleaner.