Despite rapid growth in research and development since their discovery at

Drexel University in 2011, the promising two-dimensional materials MXenes

face barriers to large-scale manufacturing and practical application due to

reliance on hazardous hydrofluoric acid etching methods. MXenes show

potential for uses including energy storage, catalysis, water purification,

optoelectronics, communication and healthcare, but scaling production while

controlling surface chemistry has challenged wide commercialization.

New research from scientists in the College of Engineering demonstrates a

pathway to sustainable, precise MXene synthesis using a computational

framework to guide fluorine-free production. The novel method, published in

Advanced Materials, highlights the power of computational

materials design to advance MXene manufacturing for real-world

technologies.

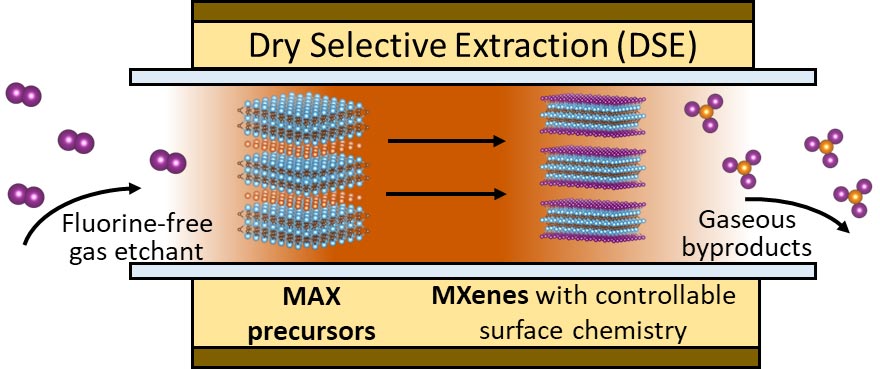

Schematic representation of this new synthesis pathway of MXene based on dry selective extraction (DSE).

Our motivation for using a computational approach is because it allows us

to design a new, more sustainable synthesis method efficiently and

rationally from a large space of materials chemistry and reaction

parameters,” explained

Yong-Jie Hu, PhD

, assistant professor of materials science and engineering at Drexel, who

led the computational study.

The study establishes a computational approach for dry selective extraction

of MXenes using iodine vapor to replace the hydrofluoric acid solutions.

The team used density functional theory (DFT) calculations to identify

thermodynamically stable candidates for the process, including the most

popular and widely used titanium carbide MXene.

“Identifying promising candidates of precursors through DFT-based

computational screening was challenging yet rewarding,” said Hu. “Our

calculations successfully revealed several promising candidates from

numerous possibilities.”

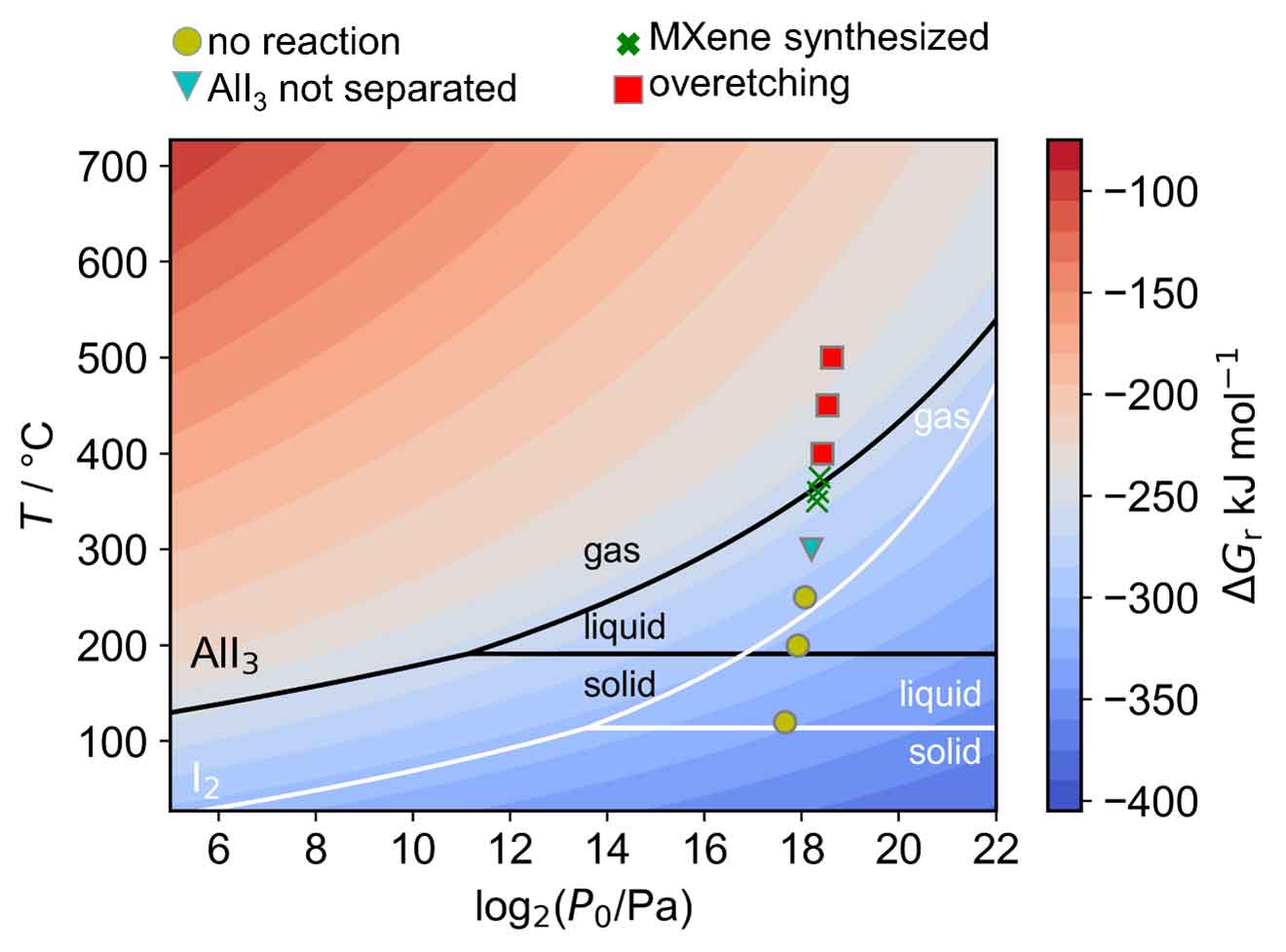

The CALPHAD (CALculation of PHAse Diagrams) approach was then used to model

optimal temperature and pressure conditions for iodine vapor etching

synthesis. Initial experiments produced the desired MXene composition,

validating the computational predictions.

“It is not enough to ‘synthesize’ a material in a computer. The process

must be transferred to a laboratory and, eventually, industrial-scale

production,” said co-author

Yury Gogotsi, PhD

, Distinguished University Professor and Charles T. and Ruth M. Bach

Professor at Drexel, who led the efforts of experimental validation.

This methodology opens the door to dry synthesis of MXenes with

compositions unattainable through conventional aqueous acid etching. It

also provides a framework to optimize synthesis conditions based on

thermodynamic characteristics. Moreover, the process is more sustainable,

as it does not require large amounts of water for synthesis and washing of

the product. The reaction byproducts can be collected and the iodine can be

reused in the synthesis process.

“We envision this methodology as a catalyst for advancing MXene synthesis

and applications,” said Gogotsi. “In the future, we plan to apply this

approach to other precursors and etching agents, expanding the range of

accessible MXene compositions and surface chemistries.”

The researchers see promise for improved performance and sustainability of

MXenes in various technological fields, driving innovation through the

computational design enabled by this study. “The ability to computationally

predict and control surface termination unlocks new possibilities for MXene

materials design,” concluded Gogotsi.

The multidisciplinary study was performed by a diverse research team,

including Eiara Fajardo, a fith year BS materials science and engineering

student; Ervin Rems, a master’s student from the European Erasmus Mundus

MESC+ program

; Mark Anaye, a PhD candidate studying under Gogotsi; Robert Lord, PhD, a

post-doctoral researcher in Gogotsi’s group; and David Bugallo, PhD, a

Marie Curie post-doctoral research in Hu’s group.

Read the full paper here: https://onlinelibrary.wiley.com/doi/abs/10.1002/adma.202305200

A computationally predicted reaction thermodynamic map to guide the discovery of optimal reaction temperature and pressure along with experimental validations.

A computationally predicted reaction thermodynamic map to guide the discovery of optimal reaction temperature and pressure along with experimental validations.