A project led by Drexel researchers to optimize the creation of two-dimensional nanomaterials has received support in the form of a multi-million-dollar NSF Future Manufacturing Research Grant (FMRG).

MD-predicted fractional free volume for Pebax−Ti3C2

The focus of the project is on cyber manufacturing. The method uses artificial intelligence, multiscale mathematical modeling, and other technologies to: design and optimize 2D nanomaterials in silico; design, optimize, monitor, and control processes that manufacture the nanomaterials with consistent desired properties; and learn the relationships between process-operation conditions and end-product properties.

The project is led by Masoud Soroush, PhD, professor of chemical and biological engineering. Michael Grady, adjunct professor of chemical and biological engineering, is listed as Co-PI, along with Andrew M. Rappe, PhD, professor of chemistry and Zahra Fakhraai, PhD, associate professor of chemistry, both at the University of Pennsylvania, and Babak Anasori, PhD materials science and engineering ‘14, assistant professor of mechanical and energy engineering at Indiana University–Purdue University Indianapolis.

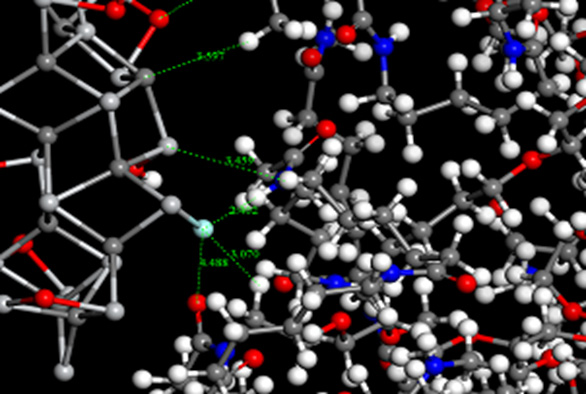

As a testbed, the project considers the manufacturing of Ti3C2 MXene. MXenes — two-dimensional nanomaterials first discovered at Drexel — have been shown to have incredible electrical, mechanical and physical properties that make them ideal springboards for innovation across multiple markets. To date, creating nanomaterials has been time intensive and small-scale, happening mostly in individual labs. This project helps meet their potential by exploring the large-scale manufacturing of MXenes with consistent desired properties.

Masoud Soroush

“MXenes with inconsistent properties are currently being produced at a small scale in different laboratories,” Soroush explains. “The process of making MXenes is extremely sensitive, and there is not an adequate understanding of the electronic- and atomic-scale processes that occur when creating them, or of the defects that are formed. By studying these processes at the electronic and atomic scales, and capturing and representing the understanding in readily available form, we hope to address the quality inconsistency and low production rate.”

The project hopes to open opportunities for the quick discovery and creation of new, customized 2D nanomaterials with consistent desired properties. This could help revolutionize a number of industries.

“MXenes have been used in novel biomedical devices, sensors, catalysts, gas separation and water purification devices, conductive coatings and smart fabrics,” Soroush explains. “Each of these industries has a tremendous market size and creating opportunities for innovation within them can bolster the manufacturing strength of the United States for years to come. That is why it’s so rewarding to have this work supported in this way.”

Soroush, along with researchers at Penn, the University of Colorado-Boulder and the University of Oklahoma, also recently received an NSF Emerging Frontiers in Research and Innovation (EFRI) grant to study on-demand modular manufacturing of mRNA.