Drexel Students Focus on the Future of Developing Countries with Sustainable Machine Design

September 18, 2008

Related

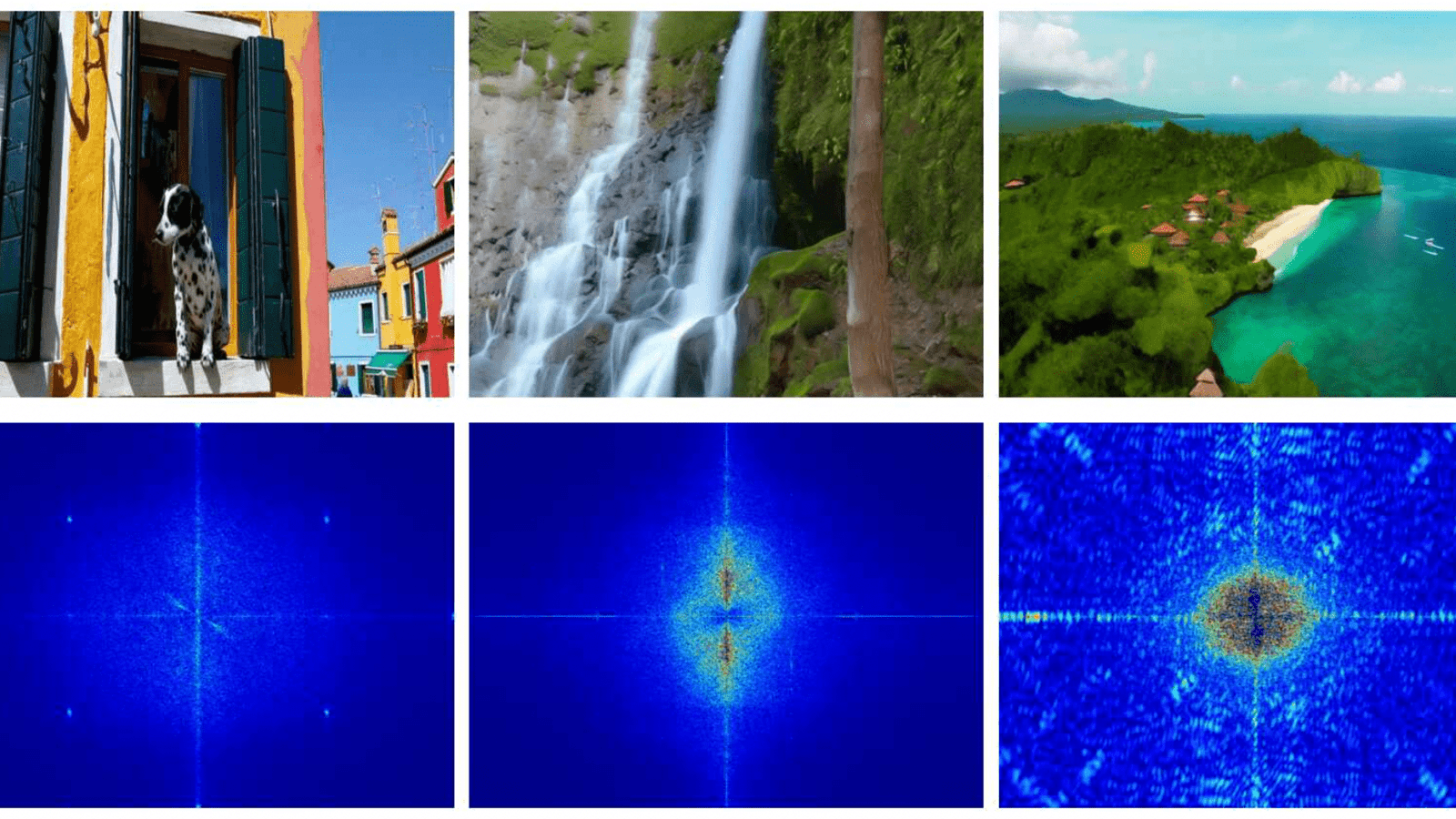

- On the Trail of Deepfakes, Drexel Researchers Identify ‘Fingerprints’ of AI-Generated Video

- New AI-Technology Estimates Brain Age Using Low-Cost EEG Device

- Bolstered by Research Consortium with Drexel, Jefferson’s Sidney Kimmel Cancer Center Earns NCI Comprehensive Cancer Center Designation

- No link between acetaminophen use during pregnancy and children's autism risk

Three Drexel University mechanical engineering students didn’t celebrate their graduation with summer vacations. Instead they spent three weeks in East Africa introducing the citizens of Karatu, Tanzania to the woodturning lathe, a sustainable machine design. The lathe can turn local resources into simple tools and increase the economic development of Tanzania. The students taught the citizens of the small African country how to build a woodturning lathe from scrap materials that in turn can be used to cut and shape wood.Students David Droz, Alexander Moseson and Josh Raizman together with Dr. Lew Lama, an anthropologist and carpenter who served as a visiting professor at Drexel, worked with students from a local orphanage to build the first of two human-powered lathes. According to Moseson, the students would all gather around to learn how to help create the lathe. With the help of translator Zenan the two groups got over the language barrier and somehow managed to understand each other even when Zenan didn’t translate. “When we discovered the drive system of the lathe wasn’t working properly, I suggested we get rid of the dysfunctional belt and push the two wheels closer together,” said Moseson. “By then the students were so excited to build they pushed us out of the way and began to finish the lathe on their own. It was amazing to see these students, who will most likely not attend college or even high school, understand so much in such a little amount of time.” The Drexel team worked every day visiting local villages, and junkyards to find materials for lathes and instructing the locals on the building process. The team trained more than 30 craftsmen in four regions and more than 100 students at three vocational training centers on how to build and use woodturning lathes. The students created an instruction manual to leave with locals that will provide a guide on building lathes. For third-world countries, being able to build these lathes could help improve the quality of life. “We expect this project to bring a better standard of life to the citizens of Karatu and other developing countries,” said Moseson. “The wood-turning lathes provide a manufacturing technology that will enable citizens to sell goods from renewable energy sources and local materials.”According to Moseson, the team will continue its advocacy with the help of Drexel’s College of Engineering. The team’s mission is to create additional engineering solutions to meet the needs of people in other developing countries. Moseson said, “Technology seeding is key and we plan to provide a vision so they can execute it with our help.”The East Africa initiative was the team’s senior design project. Drexel engineering student Shreyansh Shah was also a part of the team. All Drexel engineering seniors are required to complete a senior design project, teaching students the engineering design process and application from conception to application. For more photos and information on the project, visit the team’s website at http://www.lathesforafrica.org/.Since its founding in 1891, Drexel University’s College of Engineering has emphasized its strengths in engineering, science and technology to educate students to become the leaders of the future. The College has the largest undergraduate engineering program among the nation’s private universities and is Drexel’s flagship school with more than 3,500 undergraduate and graduate students specializing in experiential and global education. ###News Media Contact: Elizabeth Brachelli, Drexel College of Engineering 215-895-2210 or ebrachelli@coe.drexel.edu Niki Gianakaris, Assistant Director, Drexel News Bureau 215-895-6741, 215-778-7752 (cell) or ngianakaris@drexel.edu

In This Article

Drexel News is produced by

University Marketing and Communications.

now.editor@drexel.edu

For story suggestions or to share feedback

now.webmaster@drexel.edu

For questions concerning the website, or to report a technical problem