Envision custom ordering a material to particular specifications that was stronger, lighter, able to heal itself, or never failed when used for the particular purpose for which it was made. Assistant Professor Garritt J. Tucker and his Computational Materials Science and Design Group (CMSD) aim to achieve just that.

Dr. Garritt Tucker

Tucker’s group uses high-performance scientific computing and the fundamental theories of materials to study the structure of materials at the atomic and molecular level, with the goal of engineering a new generation of novel materials with tunable properties. Motivated by Professor Richard Feynman’s lecture on “There’s Plenty of Room at the Bottom,” and theoretical physicist Charles Franck who said, “Crystals are like people: it is the defects in them that make them interesting,” the CMSD group at Drexel University aims to understand how a material’s functional properties are inherently linked to their nanoscale structure and utilize modern computational tools to assist in designing materials with tailored properties.

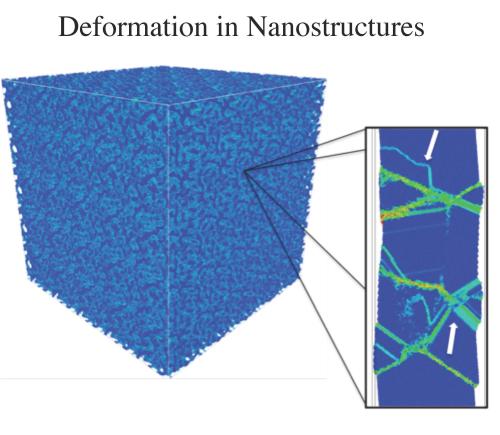

Using large-scale atomistic simulations, the CMSD group has studied structural deformation in a nanoporous metallic foam containing 50 million atoms.

“We leverage computer modeling and theory to explore the fundamental nature of materials, such as metals and metallic alloys,” says Tucker, “and look at how those materials might behave with specific structural changes. We also examine the processes that give materials enhanced behavior, such as increased strength, durability, and thermal stability, that could have a myriad of uses in practical applications.” Those practical applications include structural components, actuators, sensors, and coatings.

By utilizing both theory and computer modeling, Tucker’s research provides clues to the often un-tapped potential that materials possess. He also works closely with other scientists to validate and improve those theories to tailor materials performance from nanoscale engineering. While the majority of their research is in metallic materials, Tucker and his group are also looking at oxide materials for batteries and thin films for corrosion resistance. Specifically, they are studying how to leverage defect physics in materials used in batteries, layered composites, and nanostructures to improve a number of technologies. He also has an interest in studying self-healing mechanisms for improving materials reliability in extreme environments, such as nuclear applications and aerospace, and methods to merge the seemingly disparate fields of advanced scientific computing and materials design. This idea extends beyond his virtual laboratory and into the classroom as well, where he envisions using computer modeling and simulations to teach the materials science curriculum and provide students with a new approach for materials exploration and design.

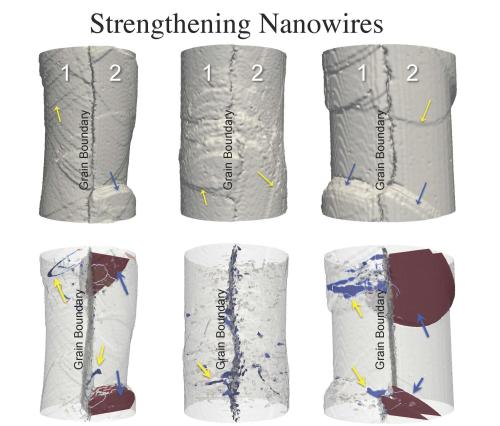

The group also studied strengthening properties of nanowires (from Tucker et al., MSMSE, 2012).

While Tucker’s background is in physics and mathematics, his research interest lies at their confluence with materials science and engineering. After obtaining bachelor’s degrees in both physics and mathematics from Westminster College in Salt Lake City, UT, he pursued a PhD in materials science and engineering from the Georgia Institute of Technology in Atlanta, GA to focus on the application of physics and mathematics. Following graduate school, he worked as a postdoctoral research appointee in the Computational Materials Science and Engineering department at Sandia National Laboratories in Albuquerque, NM.

“The goal of our research is to be able to selectively tune the properties of materials for specific applications,” says Tucker. “By developing a fundamental understanding of how materials work at the nanoscale, we can begin to look at ways to make custom properties a reality for current and future technologies.”