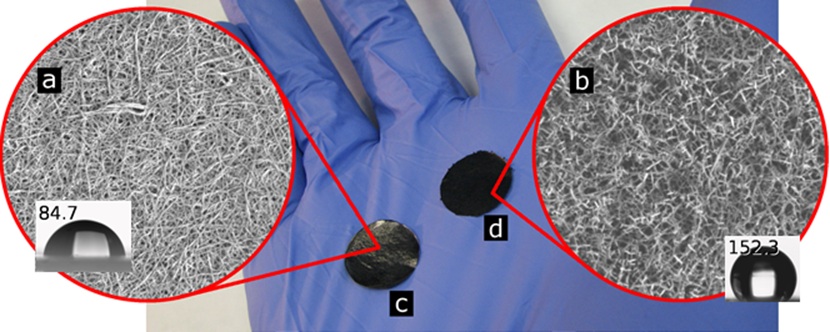

Comparison of Single walled carbon nanotube (SWCNT) buckypaper and nanohybrid shish kebab (NHSK) paper. a,b) SEM image of top surfaces of vacuum-deposited SWCNT buckypaper (a) and NHSK buckypaper (b). c,d) Optical images of the as-deposited SWCNT (c) and NHSK paper with 25 wt.% SWCNT content (d) films. Light is easily reflected off of the surface of SWCNT buckypaper, but is scattered effectively from the NHSK buckypaper surface. Two samples showed dramatically different water wetting behaviors.

Comparison of Single walled carbon nanotube (SWCNT) buckypaper and nanohybrid shish kebab (NHSK) paper. a,b) SEM image of top surfaces of vacuum-deposited SWCNT buckypaper (a) and NHSK buckypaper (b). c,d) Optical images of the as-deposited SWCNT (c) and NHSK paper with 25 wt.% SWCNT content (d) films. Light is easily reflected off of the surface of SWCNT buckypaper, but is scattered effectively from the NHSK buckypaper surface. Two samples showed dramatically different water wetting behaviors.A group of Drexel materials researchers, led by Professor Christopher Li, has developed a new form of buckypaper, a sheet of carbon nanotubes, with potential uses ranging from body armor to next-generation batteries. The results of their findings have been published in ACS Nano.

Materials Ph.D. students Eric Laird, Wenda Wang, Shan Cheng, Bing Li (all advised by Professor Christopher Li), Dr. Volker Presser, Ph.D. student Boris Dyatkin (advisor: Professor Yury Gogotsi), Professor Yury Gogotsi, and Li are the co-authors on "Polymer Single Crystal-Decorated Superhydrophobic Buckypaper with Controlled Wetting and Conductivity." The research, funded by the National Science Foundation, reports that there are several ways to make buckypaper, which conducts heat and electricity better than most known materials. Buckypaper is formed by depositing a very thin layer of entangled carbon nanotubes to create a fiber mat akin to office paper. Li and colleagues note that no existing post-processing method allows researchers to increase the size of the tiny holes, or pores, between the carbon nanotubes after they form the buckypaper. Li's group looked for a way to do that and to introduce other substances to buckypapers that could make them more useful in electronics or as sensors.

To control pore size, the team grew single crystals of polymers around the nanotubes. The group describes it as a "shish kebab" structure, where the nanotubes are the skewers and the flat crystals serve as kebabs. After the researchers formed the buckypaper, these crystals held the nanotubes apart. Li demonstrated that the crystals allow researchers to control the pores' sizes and change the buckypapers' conductivities, surface roughness and abilities to shed water.

This research has received coverage in ACS, Science Daily, Science Newsline and the February 2012 (#1) Materials Research Society's newsletter Materials360®.