As part of materials research, materials are often examined at the nanoscale, a scale 70,000 times smaller than the diameter of human hair. Samples are viewed on powerful microscopes, in particular the scanning electron microscope. Scanning electron microscopes use high-energy electrons, instead of visible light, which can easily reach magnifications of hundreds of thousands of times -- magnifications that would scale up a grain of sand into a football stadium.

In the world of electrons, there is no color. Images are captured by the microscopes in greyscale. Once an image is obtained, it is sometimes false-colored to produce an eye-popping, visually stunning image that has research importance as well as artistic merit.

In 2012, the Department of Materials Science and Engineering presented the exhibit, "Small & Exquisite: Visual Explorations in Materials Science & Engineering" at Drexel University. Below is a sample of the award-winning images captured by students in Drexel's Core Facilities and false-colored by the students themselves.

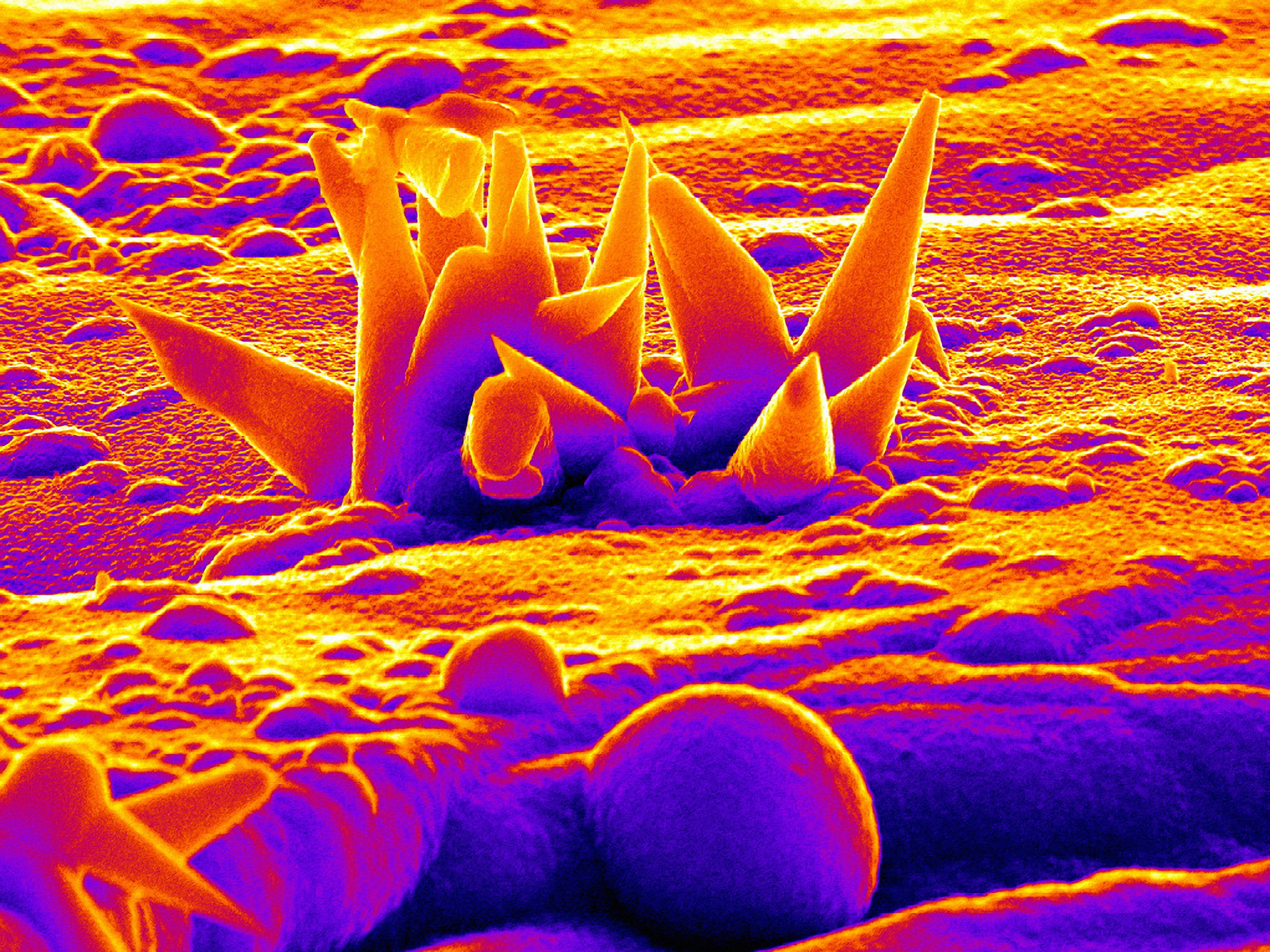

Silicon nanocones grown in a chemical vapor deposition chamber. Tapered semiconductor nanowires have applications in solar cells, antireflective coatings, and Li-ion batteries.

Silicon nanocones grown in a chemical vapor deposition chamber. Tapered semiconductor nanowires have applications in solar cells, antireflective coatings, and Li-ion batteries.

Image credit: Jennifer Atchison of the Natural Polymers and Photonics Group. Captured on the Amray 1850 FE, in the Mesoscale Materials Laboratory. Image won 1st Place in the CE&N Your Science Up Close International Photo Contest.

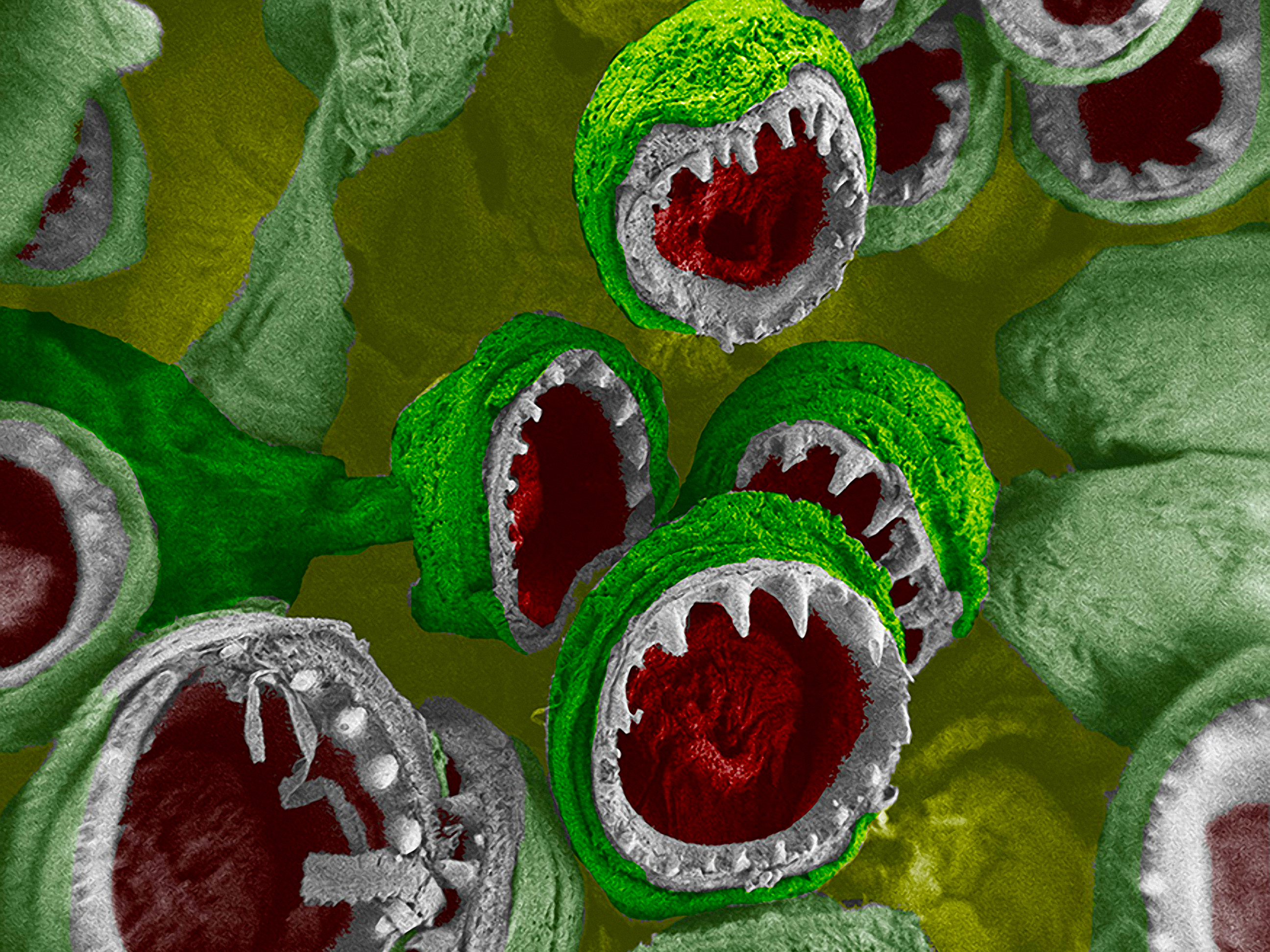

Fanglike structures that make up a squid tentacle. Each small "mouth" is 400μm in diameter.

Fanglike structures that make up a squid tentacle. Each small "mouth" is 400μm in diameter.

Image credit: Jessica Schiffman of the Natural Polymers and Photonics Group. Captured on the Zeiss Supra 50VP SEM in Drexel's Core Facilities. Image won Honorable Mention in the 2009 NSF and Science International Science & Engineering Visualization Challenge.

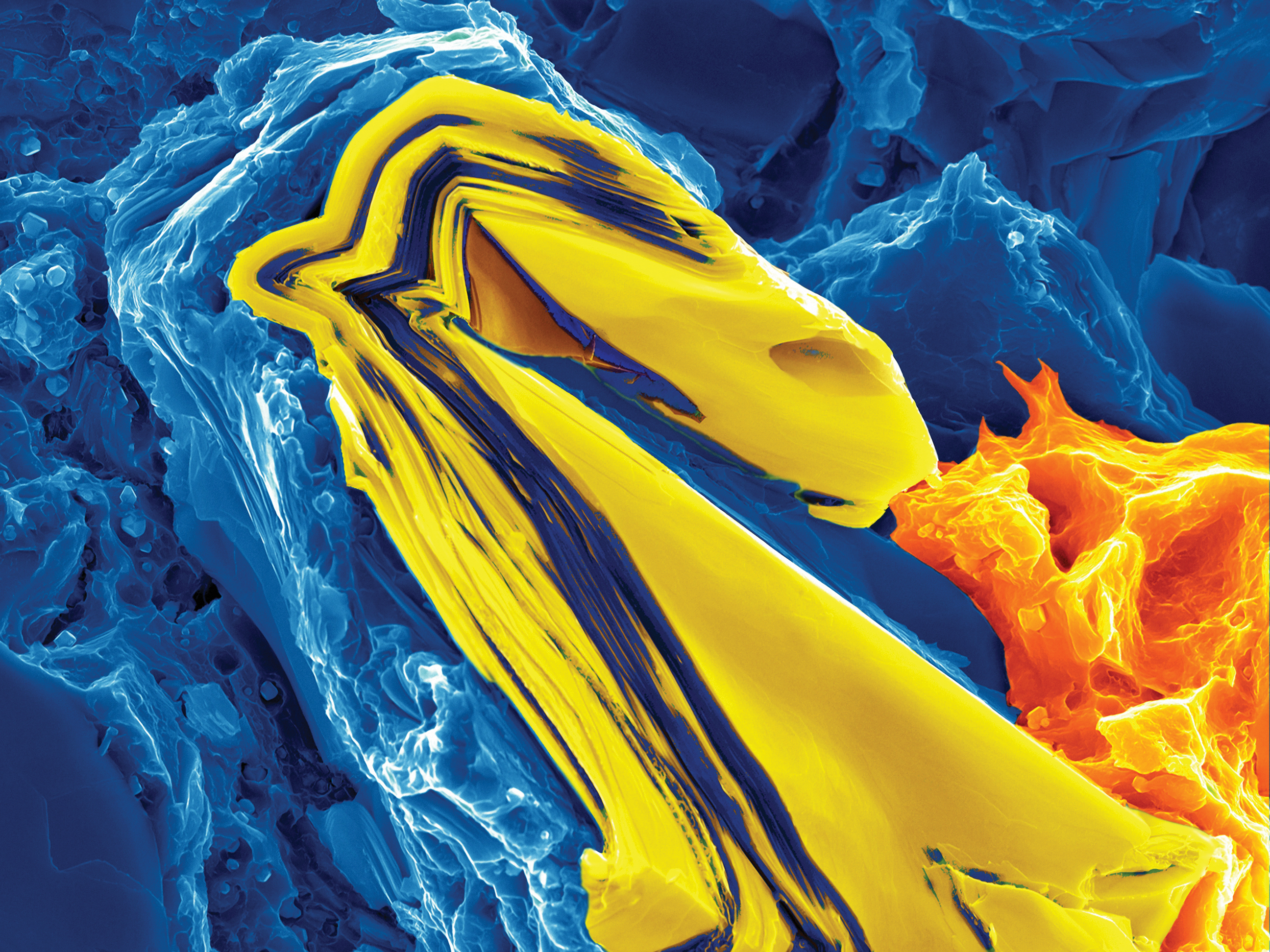

Fractured surface of a nanocrystalline magnesium matrix composite reinforced with Ti2AlC. A Ti2AlC grain kinked several times during fracture to form a “dragon”. The width of the image is 35μm.

Fractured surface of a nanocrystalline magnesium matrix composite reinforced with Ti2AlC. A Ti2AlC grain kinked several times during fracture to form a “dragon”. The width of the image is 35μm.

Image credit: Babak Anasori of the MAX/MXene Group. Captured on the Zeiss Supra 50VP SEM. 1st place in the 2011 International Metallographic Contest, Digital Microscopy (Artistic) and the 2010 Drexel Core Facilities Image Contest.