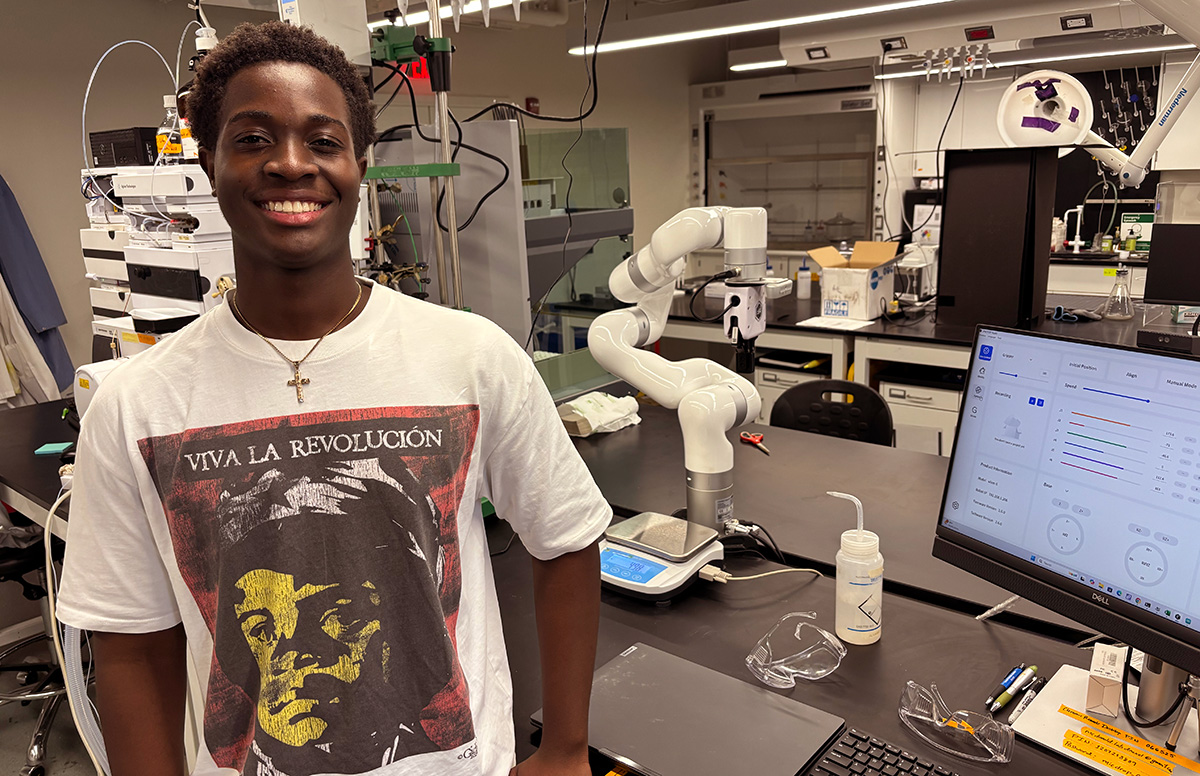

Students Tackling Advanced Research, or STAR, gives first-year Dragons a summer to join a faculty-led project and learn how research really happens. The goal is early mentorship, real responsibility, and a finished product that advances the work of a Drexel lab. This year, mechanical engineering student David Diabene found his place in that model, contributing robotics and controls to an ongoing project in the Department of Chemical and Biological Engineering.

Diabene joined a team led by Matthew McDonald, PhD, that is building a reliable bench-top system to automate crystallization, a common step in making medicines. Crystallization turns a dissolved substance into solid crystals. Small shifts in temperature, concentration, mixing, or the use of tiny seed crystals can change purity and yield, which makes the work slow and hard to reproduce by hand. McDonald’s vision is a platform that performs those steps the same way every time and records each move.

Under McDonald’s guidance, Diabene took ownership of the robotics layer and turned a crowded bench into a repeatable workflow. He taught the six-axis UFactory xArm 6 where to move and when, writing Python routines that set safe positions and paths. He connected a laboratory scale so the system could read weights directly and dose powder to a set target, then designed 3D-printed scoops and frames that the gripper could hold without slipping. To handle liquids, he built a microcontroller-driven peristaltic pump to dispense on cue, and he added a simple camera to scan QR codes on bottles to confirm chemicals before a run.

“The satisfaction comes from building something useful and watching it work,” Diabene said. “You give the system clear instructions, and it does the same thing every time.”

McDonald shaped the research goals and kept the emphasis on reliability that others can repeat. Diabene translated those goals into working code and hardware, refining details like grip force, travel speed, and weigh-out routines.

By August, the setup could weigh, scoop, and dispense with the push of a button. Next, the group will use the platform to test seeding conditions and other variables in real time, then extend the Python interface to adjust temperature, mixing, and filtration on command. The result could shorten the path to a high-purity crystal and make experiments easier to compare across runs and labs.

For Diabene, the program delivered the best of both worlds: a clear research direction and room to build. He plans to continue in the lab this year.

“STAR gave me mentorship and the chance to contribute,” he said. “Seeing our system work in the lab is the best part.”