A successful Senior Design project takes creativity, time, and in-advance planning. For this group of students—it was all about their foundation as a solid team of friends, as well as the networking and connections they made over their time at Drexel University.

“We’re all Mechanical Engineering Students, so we’ve been friends and have worked on projects together basically since freshman year,” said team member, Nicholas Bilancio. “We started college together, and we’re gonna end it together.”

Senior Design team members (left to right) Cooper Tremblay, Joshua Welsh, Nicholas Bilancio, Noelle Kownurko and Sean Kennedy.

The Senior Design team, consisting of Nicholas Bilancio, Sean Kennedy, Joshua Welsh, Cooper Tremblay and Noelle Kownurko, was sponsored by Eaton Aerospace for their idea to create a QDM Braid Puller. The team was inspired by one of the biggest products in the aerospace industry—a sensor cable used on engine platforms that is currently pulled and cut to fit proper design specifications, all by hand. This kind of manual labor caused stress and fatigue for operators. Their project was to develop an automated machine that would do this for operators—eliminating the dangers of doing it by hand, and allowing for more consistency and efficiency than the current method.

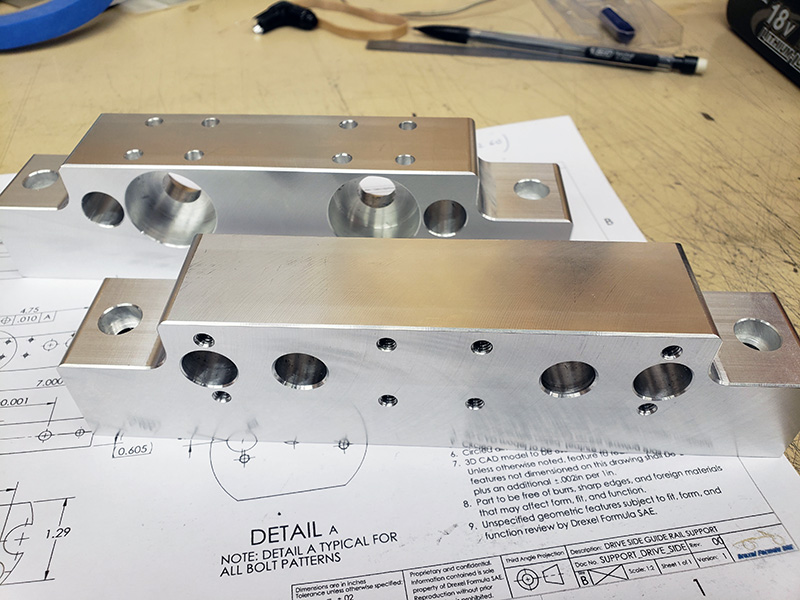

“Similar to most projects, it started out as just a CAD model designed in SolidWorks. Eventually Part Drawings were made in order to manufacture the parts to the required tolerances. The parts were then machined,” said Kennedy. “The members of the team have several hundred hours in this project excluding documents, reports, presentations required by the courses.”

Machined parts for the project

Both Bilancio and Kennedy worked with Eaton Aerospace for their second co-ops, where they were able to foster strong relationships with employees and Drexel Alumni who worked at the company. Bilancio worked with the company once again for his third co-op, eventually taking up a part-time position with the company after the program’s completion.

“After myself and Sean both really proved ourselves on our co-ops, [Eaton Aerospace] decided to work with us to create a Senior Design project. And then, ironically, as the project kind of started, I ended up accepting a full-time job offer at the company, which I started in January,” said Bilancio. “The project is actually one of my product lines, now.”

The spirit and closeness of this team is emphasized through the group’s attitude, and their ability to overcome obstacles by their fluid work ethics.

“This was a team effort through and through. Absolutely everyone pulled their weight. We all met on a regular basis to go over everything. So having a team that can really flesh out a design early on in the process and also having a team of people with a really solid Engineering foundation makes a world of difference in the long run,” said Bilancio. “It was nice working with people we had already done so much work with, because we knew everyone’s abilities, and could piggyback off each other to help out. It makes a world of difference when you can openly have conversations with everyone about the project.”

Given circumstances and closures surrounding COVID-19, the team faced their own obstacles during the design process. They worked exclusively with vendors to select hardware for their project, and were met with inventory problems due to warehouses in China being shut down for the pandemic. Fortunately, they were able to work with their vendor and find an alternate sensor from a U.S. warehouse, resulting in only a small reworking of the design. But if it wasn’t for their strong mutual support and ease in coming together rather early on, it could have caused considerable derailment for their project. Balancio shared thoughts on the notion, “We were able to get a really functional design early on, and fleshed it out over time. So it’s just having the right team and doing your due diligence early on that makes a big difference.