The first half of 2020 was an active time for Drexel Materials research grant awards covering a wide range of applications. From addressing urgent challenges in health care, to improving manufacturing processes, to creating more efficient energy storage and infrastructure, faculty are investigating, innovating, and collaborating to develop solutions to some of today’s most pressing societal needs.

Health and Medicine

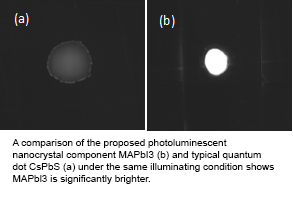

Professor Wei-Heng Shih has received a two-year NIH grant for his project “Development of Aqueous Suspensions of Organohalide Perovskite Nanocrystals for Bioimaging.” Imaging biological tissues is an important part of identifying disease. Near-infrared (NIR) emitting materials would be ideal because they can avoid the interference of tissue autofluorescence and have minimal absorbance by water, however only one NIR dye is currently approved by the FDA. This project will develop a stable suspension of photoluminescent nanocrystals that are much brighter than currently used dye molecules. The nanocrystals will be linked to antibodies and used to image cancer cells specifically.

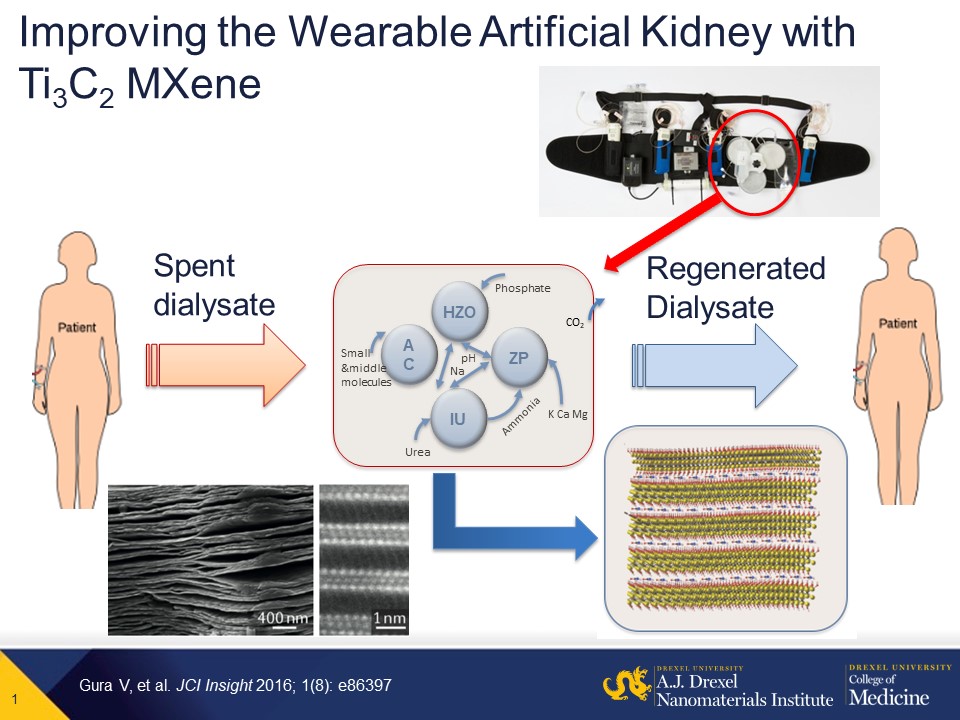

Distinguished University and Bach Professor Yury Gogotsi has received a one-year NSF grant through the Division of Chemical, Bioengineering, Environmental, and Transport Systems for his project “EAGER: MXene Sorbents for Continuous Renal Replacement Therapy.” Early evidence has suggested that COVID-19 causes direct kidney injury, which is present in approximately 30 to 40% of hospitalized patients. COVID-19 also disproportionately afflicts people with underlying kidney disease. Unfortunately, typical dialysis treatments for severe kidney injury are resource-intensive and require several hundreds of liters of specialized fluid (dialysate) per treatment. At the height of the pandemic in New York City, reports revealed that supplies of dialysate were dangerously depleted, leading to rationing of dialysis care for hospitalized patients. To address the limitations of the current state-of-the-art dialysis treatment methods, this project will investigate and design novel toxin-removing (sorbent) materials as a potential alternative dialysis technology. The goal is to reduce the amount of fluid necessary for dialysis and advance progress toward in-home or wearable dialysis therapies.

Manufacturing

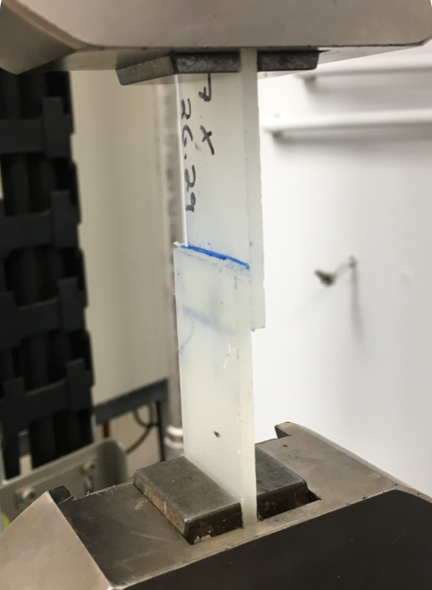

Assistant Professor Andrew Magenau has received a Pennsylvania Manufacturing Innovation Program Grant to partner with Boeing to develop a versatile adhesion process that can be conducted rapidly, drawing on Magenau’s polymer and alkylborane expertise and processing and adhesion expertise from Boeing engineers. The goal of the project is to address a bottleneck in many manufacturing processes because polymer substrates are inherently difficult to adhere, often requiring expensive pretreatment and mechanical fastening, or the process of adhesion requires specialized equipment, high temperatures, and prolonged cure times.

A.W. Grosvenor Professor Antonios Zavaliangos has received a Pennsylvania Manufacturing Innovation Program Grant to partner with Natoli Engineering to address issues of scaling in pharmaceutical tablets. Applications include the development of pediatric versions of pharmaceutical tablets when the technology developed for the larger adult tablets is not always immediately applicable to the smaller ones, and the development of material sparing techniques when the amount of the material available is limited or very expensive.

Functional Materials

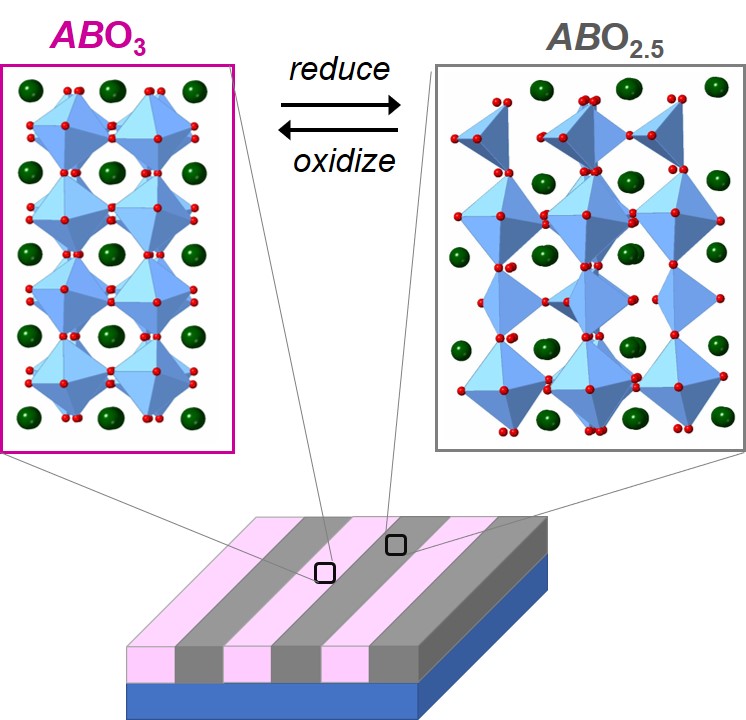

Professor Steven May has received a three-year NSF grant award through the Division of Civil, Mechanical, and Manufacturing Innovation for his project “Uniting Lithographic Patterning and Topochemical Reaction for Processing of Functional Oxides for Electronic Applications.” This grant supports research into developing and understanding a new nanomanufacturing process to fabricate novel patterned materials, thereby generating fundamental innovations in advanced manufacturing and advancing the nation’s technological capabilities.

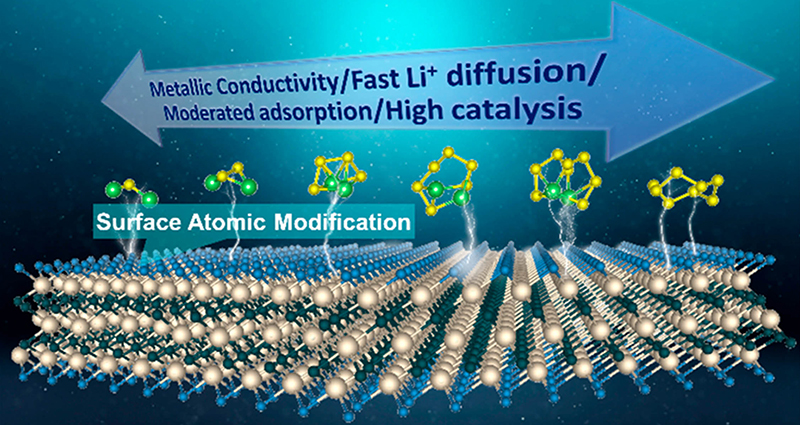

Distinguished University and Bach Professor Yury Gogotsi has received a NASA SBIR Phase II grant to partner with Giner, Inc. on the project “High Energy Density and High Cycle Life Lithium-Sulfur Battery for Electrified Aircraft Propulsion.” The project will build on a successful Phase I feasibility demonstration to scale up its novel coating technology for stabilizing Li metal anodes in prototype Li-S pouch cells. Scaling up will enable commercialization of high energy density Li-S batteries with increased cycle life. This improvement will make Li-S batteries more practical for electric vehicle applications, and will address an important growing demand for safe, efficient, low-cost, environmentally sustainable air transportation. Additional markets include power for unmanned aerial vehicles, aerospace vehicles, military satellites, large-scale grid energy storage, and consumer electronics.

Interdisciplinary Collaboration

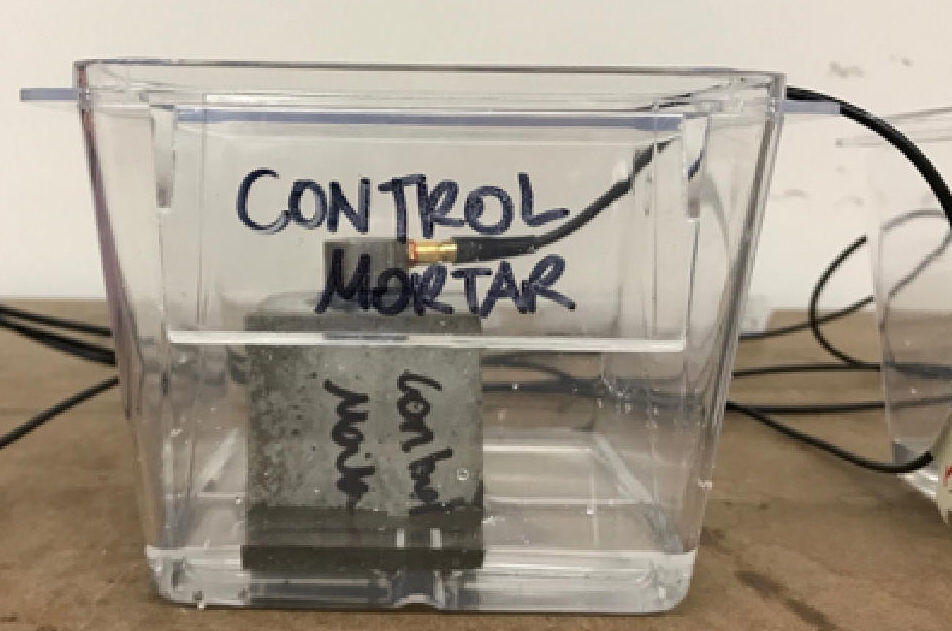

Professor Caroline Schauer, in collaboration with Assistant Professor Yaghoob Farnam (PI), and Associate Professor Christopher Sales from Civil, Architectural, and Environmental Engineering Civil, Architectural, and Environmental Engineering, and Assistant Professor Ahmad Najafi from Mechanical Engineering and Mechanics, has received a three-year NSF grant award through the Division of Civil, Mechanical, and Manufacturing Innovation for the project “Engineering Bioinspired Multifunctional Microbial Polymeric Fiber (BioFiber) for Concrete Self-Healing.” This research will investigate a new self-healing concrete enriched with bioinspired multifunctional microbial polymeric fibers to improve the durability and resilience of civil infrastructure.