The U.S. Department of Defense has tapped Drexel University as a key leader in the creation of a $75 million national research institute that will support American textile manufacturers in bringing sophisticated new materials and textiles to the marketplace. The institute, called Advanced Functional Fabrics of America, will be a national manufacturing resource center for industry and government to draw on the expertise of academic researchers working with new fibers, fabrics and materials and developing the technology that can integrate them into products from active wear to protective armor.

The U.S. Department of Defense has tapped Drexel University as a key leader in the creation of a $75 million national research institute that will support American textile manufacturers in bringing sophisticated new materials and textiles to the marketplace. The institute, called Advanced Functional Fabrics of America, will be a national manufacturing resource center for industry and government to draw on the expertise of academic researchers working with new fibers, fabrics and materials and developing the technology that can integrate them into products from active wear to protective armor.

Secretary of Defense Ashton Carter formally recognized Advanced Functional Fabrics of America (AFFOA) as one of the White House’s National Network for Manufacturing Innovation Institutes in a ceremony at the Massachusetts Institute of Technology today. The NNMI initiative is a $317 million public-private effort to boost the value of American-made products on the international market, by using new materials and manufacturing methods. MIT, Drexel, the University of Central Florida and Cornell University are cornerstones of the institute because of their complementary research endeavors in novel fibers for textiles, rapid textile prototyping and computer simulation.

“Fibers and fabrics are among the earliest forms of human expression, yet have changed very little over the course of history,” said Yoel Fink, PhD, director of MIT’s Research Laboratory of Electronics, who led the AFFOA proposal. “All this is about to change as functional fiber and yarn technologies meet traditional textile production and yield new products by design. Our institute will become the focal point of innovation in manufacturing and production, realizing the vision of advanced functional fabrics for the benefit of consumers as well as our men and women in uniform.”

Drexel will receive funding from the institute to address fundamental barriers to innovation in functional fabrics and to facilitate new textile product development. Drexel will continue its innovative product development efforts, such as a bellyband for uterine monitoring, touch-sensitive skin for robots, a haptic glove for hand therapy and textiles that can store energy. It will also support engineers and computer scientists who are creating methods for modeling, designing and testing the structure of threads and fabrics in order to predict their performance in textiles, as well as continuing Drexel’s efforts as an incubator for start-up companies.

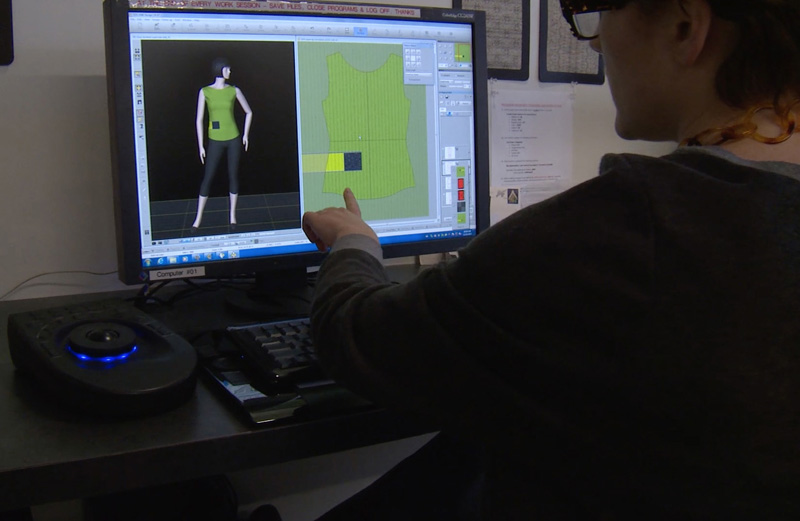

Drexel will receive funding from the institute to address fundamental barriers to innovation in functional fabrics and to facilitate new textile product development. Drexel will continue its innovative product development efforts, such as a bellyband for uterine monitoring, touch-sensitive skin for robots, a haptic glove for hand therapy and textiles that can store energy. It will also support engineers and computer scientists who are creating methods for modeling, designing and testing the structure of threads and fabrics in order to predict their performance in textiles, as well as continuing Drexel’s efforts as an incubator for start-up companies.

“The fact that the DoD has identified functional fabrics as a critical focus for U.S. advanced manufacturing is validation for Drexel, where we’ve been working on smart textiles for nearly a decade,” said Drexel President John A. Fry. “We’re proud to be a leader in launching this new industry with our public and private partners in AFFOA. Drexel’s commitment to interdisciplinary translational research as an economic driver led directly to this moment.”

The Advanced Functional Fabrics of America group includes 31 academic institutions, including The University of Texas, The Ohio State University, the University of Michigan and the University of California – Davis. It counts 16 companies as industry partners, NIKE, Microsoft, Goodyear, The North Face, Bose and Medtronic among them. In addition, 26 start-up incubators and venture capital groups, including Angel Capital Association, Westbury Partners and North Bridge Venture Partners have joined AFFOA.

Drexel will serve as the anchor for partners in the mid-Atlantic region, linking institutions such as Carnegie Mellon, Penn State, Temple University, Thomas Jefferson University and Philadelphia University to manufacturing and investment partners like DuPont, Ben Franklin Technology Partners of Southeast Pennsylvania, the City of Philadelphia Office of Manufacturing and Industry and the Pennsylvania Department of Community and Economic Development.

“Drexel played a central role in assembling this group of governmental, academic, and industrial visionaries who are all motivated by the goal of advancing a new model of American textile manufacturing and helping to develop new products for the public and defense sectors,” said Aleister Saunders, PhD, Drexel’s senior vice provost for research and a leader of its functional fabrics center. “Drawing on Drexel’s intellectual capital and our momentum as a regional economic engine, we’ve been able to gather a critical mass of regional partners thus ensuring that the progress we’ve made in the Southeastern Pennsylvania region can be replicated at a national level.”

“Drexel played a central role in assembling this group of governmental, academic, and industrial visionaries who are all motivated by the goal of advancing a new model of American textile manufacturing and helping to develop new products for the public and defense sectors,” said Aleister Saunders, PhD, Drexel’s senior vice provost for research and a leader of its functional fabrics center. “Drawing on Drexel’s intellectual capital and our momentum as a regional economic engine, we’ve been able to gather a critical mass of regional partners thus ensuring that the progress we’ve made in the Southeastern Pennsylvania region can be replicated at a national level.”

The Drexel-led group will lead investigations into modeling, designing and predicting the utility of new fibers, yarns and materials, as well as using those new materials to build prototypes of functional fabrics for apparel, healthcare, transportation, consumer electronics, architecture, and the defense industry.

“Currently there are no industry standards for introducing new materials into textile manufacturing, and this is one of the main obstacles blocking U.S. manufacturing from making a big leap forward,” said Genevieve Dion, an associate professor in Westphal College of Media Arts & Design and director of the Shima Seiki Haute Technology Lab in the Expressive and Creative Interaction Technologies (ExCITe) Center, and one of AFFOA’s research leads. “If we can bridge that gap by offering the research and testing necessary to establish standards and develop processes for using new materials in manufacturing, this institute can remove that roadblock so our nation’s economy can move forward.”

In addition to Dion’s guidance in design and prototyping, the group will draw from the expertise of Antonios Kontsos, PhD, an associate professor and director of the Theoretical and Applied Mechanics Group in the College of Engineering; and David Breen, PhD, an associate professor and director of the Drexel Geometric Biomedical Computing Group in the College of Computing & Informatics; who are deploying computational modeling programs that will enable AFFOA partners to anticipate manufacturing challenges before they arise and create strategies for surmounting them.

These predictive manufacturing tools are some of the resources that will be available to established industry partners, start-up companies and small to mid-size manufacturers. Companies also will benefit from a large network of prototyping and pilot manufacturing facilities led by experts in fiber and fabric innovation, with physical and digital archives of fibers and fabrics properties at their disposal.

These predictive manufacturing tools are some of the resources that will be available to established industry partners, start-up companies and small to mid-size manufacturers. Companies also will benefit from a large network of prototyping and pilot manufacturing facilities led by experts in fiber and fabric innovation, with physical and digital archives of fibers and fabrics properties at their disposal.

“Large manufacturing companies and start-ups alike, will be able to turn to the institute with a challenge — such as creating body temperature sensing apparel — and gain access to the intellectual property, designers, suppliers, and prototyping facilities necessary to bring a new idea to market,” said Debbie Buchwald, executive director of Corporate Relations and Economic Development at Drexel and the chief marketing officer of AFFOA. “AFFOA presents unprecedented opportunities for industry partners of all shapes and sizes by providing access to research innovation and coordinated networks of supply chain partners.”

Advanced Functional Fabrics of America is the eighth such center of innovation created by the Obama administration since 2012. Other centers have supported research and workforce development focused on 3-D printing, digital manufacturing, lightweight materials, semiconductors, advanced composite materials, photonic integrated circuitry and flexible electronics.

“This new institute is synergistic with Drexel’s overarching academic mission – to create unique, signature scholarly areas that infuse theory and practice,” said M. Brian Blake, PhD, Drexel’s executive vice president for academic affairs and provost. “Senior Vice Provost Saunders with Professors Breen, Dion, and Kontsos represent the very best academic innovators on campus.”

For more information about AFFOA visit: http://www.rle.mit.edu/fabric/ or email FutureFabrics@drexel.edu.