Most people know about Drexel University’s celebrated cooperative program, in which students fulfill six-month internships in fields of their choice to gain experience and to see how they like the work. But what, exactly, is that work? What does a co-op student do all day? What are the tasks assigned? And what time is lunch?

With these pressing questions in mind, the College of Engineering is pleased to introduce a new column, A Day in the Life of a Co-op, which will appear in this space monthly. A Day in the Life deconstructs the work day with specific details on what our co-op students do in their eight-hour shifts. To start the column off with a bang, here are three esteemed students from the Department of Mechanical Engineering—Frederick Wachter, Jagteshwar Boyal, and Matthew Wiese—to tell you about their experiences.

Frederick Wachter

NAME: Frederick Wachter

CLASS: 2018, Department of Mechanical Engineering, BS/MS (Accelerated Program)

CO-OP: Production Technology West, Trollhattan, Sweden; Sept. 2014-March 2015

WORK PERFORMED: Automation technology with Non-Destructive Testing Group (NDT), which seeks to characterize/automate the detection of defects within welds in automated welding processes through use of infrared light

7 a.m. Wake up in studio apartment; shower and breakfast; ride bike five minutes to work.

8:30 a.m. Begin work; log in, check on work from previous day; go downstairs to NDT group lab, set up for documentation and tests, warm up cameras and testing equipment; perform tests; do data analysis; check with group post-doc for instructions and guidance.

10 a.m. Participate in mandatory fika practice – a 30-minute coffee break with all colleagues that is observed by working Swedes across the country.

10:30 a.m. Continue testing; or, work with students in robotics certification course.

12 noon Break for lunch, generally outside with other employees to maximize exposure to sunlight; occasionally ride into town center for lunch.

1:30 p.m. Perform 3D printing and machining on a prototype for a device to attach to a forward-looking infrared (FLIR) camera, allowing it to see into small, confined spaces.

3 p.m. Afternoon fika break.

4:30 p.m. Collect all test data from day and do necessary preliminary analyses to determine if tests provided useful data; document test setup and initial analysis.

5:30 p.m. Bike back to apartment; take salsa classes taught by co-worker; Friday night movies; or, visit Gothenburg, a major city via a 30-minute train ride.

TAKEAWAY: “This co-op experience showed me the importance of having both the understanding of fundamental engineering concepts of the projects I am working on along with the importance of being able to implement these concepts onto a physical device. Designing a system or process without having the understanding or personnel to implement it renders any design useless. This co-op helped me figure out that I want to have the ability to understand the engineering concepts involved while also being able to implement the designs onto physical hardware.

“I also learned what it is like to live alone in a foreign country for an extended period of time, and the importance of the people I surround myself with. I realized that those I surrounded myself with can have a large influence on my life, especially the ones I worked with. I am fortunate to have worked with such positive and intelligent people during my time in Sweden. They have had a large influence on my academic and professional career.”

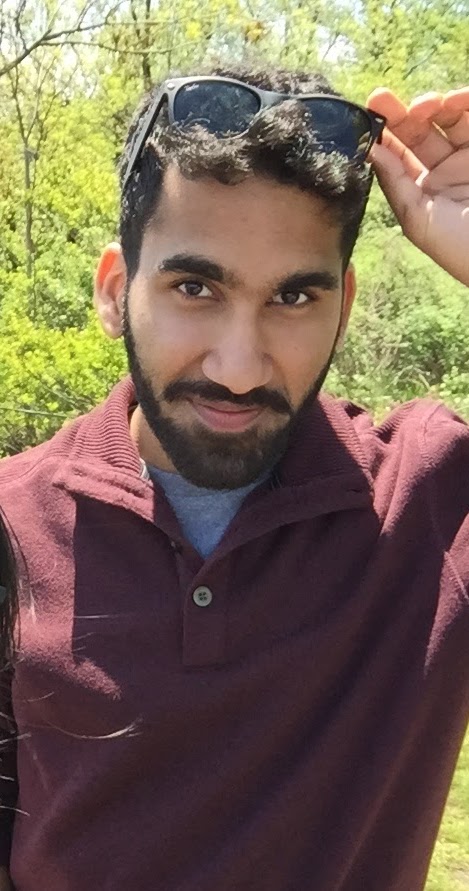

Jagteshwar Boyal

NAME: Jagteshwar Boyal

CLASS: 2019, Department of Mechanical Engineering, BS

CO-OP: Foster Jacobs & Johnson, Inc., Media, PA; April 2017-Sept. 2017

WORK PERFORMED: Audits/inspections of building energy efficiencies to decrease utility costs

7:30 a.m. Leave campus apartment for an inspection site; commute by car half an hour, depending on traffic.

8:30 a.m. Arrive at client facility, for example school buildings that need to improve energy efficiencies.

9 a.m. Meet with head custodial personnel to hear descriptions of building inefficiencies, HVAC upgrade needs, leakage or boiler problems, etc.

9:30 a.m. Begin inspection in mechanical rooms, reviewing motors, boilers and chillers (one school had boilers from the 1960s operating at 60% efficiency); consider upgrade or replacement projects; inspect building lighting system; take notes; document conditions with photographs.

10:15 a.m. Continue inspection on building roof for review of air-handling units; pop ceiling tiles; review and inspect air ducts.

11 a.m. Move to another building in district for next audit.

12 noon Break for lunch, usually at a local restaurant but occasionally—with thanks to PowerBars—while en route to the next inspection.

1 p.m. Begin another round of audits in district buildings, sometimes up to six a day.

4 p.m. Meet with district administrators to discuss and prioritize potential energy projects and cost outlays.

5 p.m. Day ends; commute home or back to campus to meet with friends.

TAKEAWAY: “After the first three weeks when we were doing a lot of client facility visits and audits, I spent most of my time trying to do the construction planning for those projects. I would go back to meet at those buildings for the planning, sometimes for two- or three-hour meetings to plan out what a big construction project would look like. My takeaway is that I learned about the competitive world of engineering consulting and the inner workings of buildings, and how important the proper function of HVAC equipment is for human comfort and energy efficiency.”

NAME: Matthew Wiese

CLASS: 2018, Department of Mechanical Engineering, BS/MS

CO-OP: Naval Research Laboratory, Washington, D.C.; April 2017-Sept. 2017

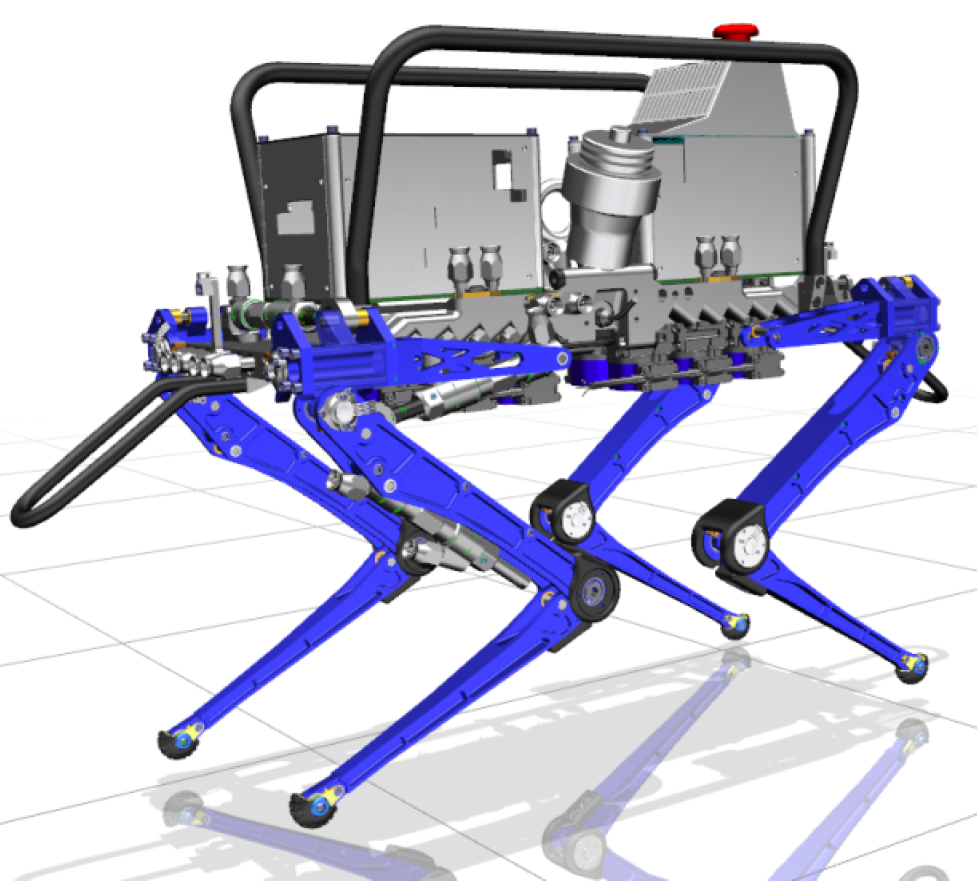

WORK PERFORMED: Spacecraft Mechanisms Group on prototyping/testing/validation of Meso-scale Robotic Locomotion Initiative (MeRLIn); collaborated on ground robotics; co-authored paper on advanced manufacturing

7:00 a.m. Wake up, shower, commute 30 minutes by car listening to National Public Radio’s “How I Built This” podcast.

8 a.m. Half hour scrolling through emails; communicate with international vendors; organize work for the day; get coffee.

8:30 a.m. Work in the lab on physical assembly of 3D-printed MeRLIn robotic dog; fit checks; “tolerancing”; responsible for advancing the natural foot mechanism so robot would know when its foot was striking the ground.

11 a.m. Break for lunch consuming own food made in crockpot previous night; eat with the mechanisms group; “technical” talk generally shunned.

12 noon Go up to desk in computer area on mezzanine level; discuss physical assembly of robot and progress with supervisor (happens to be Joshua Geating, CoE ME ’13), or shift gears to do design work on robotic satellite arm for Robotic Servicing of Geosynchronous Satellites (RSGS) project.

3 p.m. Work on research paper, “Design, Fabrication, and Qualification of a 3D Printed Metal Quadruped Body: Combination Hydraulic Manifold, Structure and Mechanical Interface,” which is eventually published.

5 p.m. Leave for the day; take metro into “heart” of D.C. and ride electric skateboard around, sightsee; meet friends in Georgetown.

TAKEAWAY: “There was just so much that needed to be done and it was a fairly small team. As soon as I finished something, I was always asking, okay, what’s next? And there were always things in the pipeline for me to do. When I got there, they had just finished testing one leg of the dog robot and they were just about to test the whole thing. I could pick and choose things I was interested in that day. It took about a month for me to settle into the role and really have a grasp of what the next steps were. It was a really interesting mix of ground robots and space robotics, both the design of the space robotics and using that technology for other things. It was such a really cool group of people who had a lot of really unique experiences.”